We are using this stepper motor driver (https://www.sparkfun.com/products/12779). In its datasheet, there is no mention of efficiency? How much is the efficiency in motor drivers like these?

-

This question is a little problematic - old drivers using things like power resistors had low efficiency, but modern *drivers* are quite efficient. The overlooked problem is that stepper *motors* are generally quite inefficient. So your question can be interpreted *literally* about efficiency of the *driver*, or the question you haven't quite asked but probably should have about efficiency of the *system* can be answered instead. So far you have one of each type of response... – Chris Stratton Jul 19 '17 at 16:21

-

Does neither of the answers proposed, answer your question? – Harry Svensson Jul 22 '17 at 17:18

3 Answers

A stepper motor driver is more or less a DC/DC converter with variable voltage output. So it's probably something around 90%. The same efficiency as a regular DC/DC converter.

- 8,139

- 3

- 33

- 53

-

It may actually be better than that, arguably the only loss in the *driver* is the FET RDSon. However, efficiency of the *system* is going to be low, with most of the losses in the motor. – Chris Stratton Jul 19 '17 at 16:19

-

Hmmm, 90% is still kind of a good **approximation**, in order for a stepper to get any current, the current has to pass through 2 FETS, rather than 1 as a DC/DC would do. And then the current will rotate back into the stepper motor through the body diode of one of the FET's (or just a regular diode component), so there's some losses in the diode. And on top of this you got the switching losses, higher frequency => more losses in switching. If you want to get rid of the audible noise you need 20kHz+ => quite a bit of switching losses. 95+% maybe if you got some high quality top notch stuff. – Harry Svensson Jul 19 '17 at 16:31

-

-

-

-

-

We did our own experiment by measuring the input and output power of the motor driver and the efficiency came out to be around 75%. – Soumil07 Jul 24 '17 at 06:04

In motion control efficiency is usually mechanical output power (w*T) divided by electrical input power (U/I). Obviously it is different for different working points. For a standing stepper it's zero. On higher speeds sometimes nice figures may be reached, but bot very nice. Because for stepper you always take spares, otherwise it slips.

This is the stepper motor linked in the question: -

How much is the efficiency in motor drivers like these?

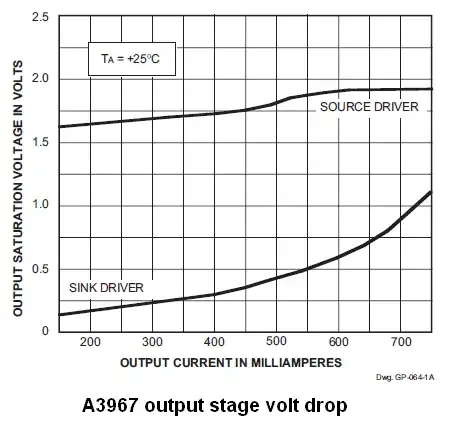

It's not great. Consider the saturation voltage of the output transistors in the A3967 chip that drives the stepper: -

If you are taking the full 750 mA into your stepper then a total volt drop of about 3 volts can be expected. If you are running from a supply of (say) 15 volts, you are going to only see about 12 volts across the stepper motor coils. This means that peak input power is 15 x 0.75 amps = 11.25 watts whereas peak output power is only 9 watts. That means the peak efficiency is about 80%. If the supply voltage is (say) only 6 volts then nearly half that voltage is lost in the driver rendering an efficiency of only 50%.

There are better devices that only drop about 0.5 volts. See this for a critique of other similar basic stepper drives / motor drives for a comparison.

- 434,556

- 28

- 351

- 777

-

Thanks for the downvote whoever it was (and I have my suspicions given that 4 downvotes in rapid succession have just happened to answers I have given and, this is very much reminiscent of last year when a certain person had a mini vendetta against me). – Andy aka Jul 19 '17 at 18:47

-

Thanks Andy for the answer. Did you actually mean a voltage drop of 2V instead of 3 since the output voltage is saturating at around 2V in the graph? – Soumil07 Jul 19 '17 at 19:09

-

It's 3 volts given that there are two active elements in a H bridge: a source and a sink and the sink drops about a volt. Both elements are in series with the motor winding. – Andy aka Jul 19 '17 at 19:10