Historical Context

I was trained at Tektronix to be an electronics draftsman.

Tektronix provided classes for anyone interested. It's quite similar to drafting for construction. You had the usual pencils, sharpeners, specialized erasers and paper, a tilted table, T-square, triangle, etc. The same basic tools of the trade for any draftsman. There were some additional tools added, such as some nice stencils for electronics components and descriptive picture items (like an oscilloscope tube -- see here for some idea of those.) But that's about all we had to work with, then.

I'd been an electronics hobbyist of some kind since about age 10, or so. Like most, I struggled to understand circuits I saw in Popular Electronics and Radio Electronics magazines. They were actually pretty hard to understand, at least as presented, because they were made for people who wanted to wire them up. Not so much for people who wanted to learn more and to understand them better. These wiring schematics would bus around all the power wiring details, most of which (I found over time) doesn't really help in understanding how a circuit works. So, as a hobbyist, I gradually tumbled to the idea of redrawing schematics so that I could better understand them. I'd literally tear down a circuit layout to its bare parts (almost) and then rebuild them back up, after I'd arranged the parts better (in my mind.)

I joined Tektronix as a software developer in 1979. I'd been working on operating systems -- such as the Unix v6 kernel in 1978 -- and software generally for large computing systems since 1972, and MCUs since 1975. But I also had a personal interest in understanding and using the products that Tektronix made, too. And when I joined Tektronix, I already had good experiences in redrawing schematics for my own understanding.

I used the word joining, above. I meant that. Joining is exactly how it felt to be a Tektronix employee back then. Your boss encouraged your personal interests, if there was any way it could be of mutual rewards. They would pay you to continue your education at universities in the area, for example. And they offered high quality classes, themselves, too. You are provided with profit share. And if your position was no longer required, they'd encourage you to go around to various departments and see if there was another job elsewhere. They'd pay you your salary while you met people and sought some other position. (I was told there was almost no limit to this, though I'm sure someone would intervene if you took too long to find work elsewhere.)

Employees paid that back after a fashion. If I decided to go to the office and work on a Sunday, for example, I'd often find many other employees also in the building and working diligently on some project needing extra effort to meet a schedule. Rarely did I walk into a building on Sunday and have it feel empty. There was almost always something going on and plenty of employees willing to provide their weekend or night time to Tektronix when needed.

Since I'd been a hobbyist for some time before joining Tektronix, I was of course also actively encouraged by my boss to take these classes when they became available.

Learning to Draw Schematics

In my first class, the instructor pointed out two simple organizing concepts. So simple, in fact, that I was immediately able to recognize their value despite the fact that I'd never been exposed to them beforehand.

Just these two:

- The idea of electron flow from bottom to top on the page. Or, more correctly, the idea of conventional current flow from top to bottom.

- The idea of signal flow going from left (inputs) to right (outputs.)

With these, one could take any random schematic they saw, tear it completely down to the ground, and re-draw it from scratch so that it obeyed these rules. The result was something almost magical. A schematic which communicated concepts quickly to other electronics engineers (and us hobbyists, too!)

The instructor also pointed out something I'd already learned on my own:

That's important for understanding. No signal flows on those wires. So drawing wires all around a schematic, wires without any signal on them, just gets in the way and distracts you from actually understanding what you are looking at. It's lots better to get rid of those wires and just annotate the voltage, instead.

The part of all this that takes a little patience (and it really is a continuing thing for one's entire life to be honest) is learning to recognize sections that are common to many schematics. Such things as: current mirrors, voltage references, analog amplifier stages, etc. This is something you cannot just be told about. Instead, we must see them, learn about them, grow to understand more of them, and then finally acquire them. And this just takes time. There's no magic bullet or pill to take here.

How did people calculate sine and cosine or logarithms or even multiply big numbers before there were calculators? They used books with tables inside, along with the training to use those tables properly. Or they used slide rules.

Life gets done. The tools change. But life still gets done.

Rules for Re-Drawing Schematics

One of the better ways to try and understand a circuit, one that at first

appears to be confusing, is to just redraw it. This simple practice is

more important than it may at first seem to be. But I recommend early and

continual practice at redrawing circuits. It's an essential skill and it

takes regular practice to yield some of its greater powers.

Below are some rules you can

follow that will help get a leg-up on learning that process. But there

are also some added personal skills that gradually develop over time,

too.

As mentioned at the outset above,

I first learned these rules in 1980, taking a Tektronix class that was

offered only to its employees. This class was meant to teach

electronics drafting to people who were not electronics engineers, but

instead would be trained sufficiently to help draft schematics for

their manuals.

The nice thing about the following rules is that you don't have to be an expert

to follow them. And that if you follow them, even blindly almost, that

the resulting schematics really are easier to figure out.

The rules are:

- Arrange the schematic so that conventional current appears to flow from the top towards the bottom of the schematic sheet. I like to

imagine this as a kind of curtain (if you prefer a more static

concept) or waterfall (if you prefer a more dynamic concept) of

charges moving from the top edge down to the bottom edge. This is a

kind of flow of energy that doesn't do any useful work by itself, but

provides the environment for useful work to get done.

- Arrange the schematic so that signals of interest flow from the left side of the schematic to the right side. Inputs will then

generally be on the left, outputs generally will be on the right.

- Do not "bus" power around. In short, if a lead of a component goes to ground or some other voltage rail, do not use a wire to connect it

to other component leads that also go to the same rail/ground.

Instead, simply show a node name like "Vcc" and stop. Busing power

around on a schematic is almost guaranteed to make the schematic less

understandable, not more. (There are times when professionals need to

communicate something unique about a voltage rail bus to other

professionals. So there are exceptions at times to this rule. But when

trying to understand a confusing schematic, the situation isn't that

one and such an argument "by professionals, to professionals" still

fails here. So just don't do it.) This one takes a moment to grasp

fully. There is a strong tendency to want to show all of the wires

that are involved in soldering up a circuit. Resist that tendency. The

idea here is that wires needed to make a circuit can be distracting.

And while they may be needed to make the circuit work, they do NOT

help you understand the circuit. In fact, they do the exact opposite.

So remove such wires and just show connections to the rails and stop.

- Try to organize the schematic around cohesion. It is almost always possible to "tease apart" a schematic so that there are

knots of components that are tightly connected, each to another, separated then by only a few wires going to other knots. If you

can find these, emphasize them by isolating the knots and focusing

on drawing each one in some meaningful way, first. Don't even think

about the whole schematic. Just focus on getting each cohesive section

"looking right" by itself. Then add in the spare wiring or few

components separating these "natural divisions" in the schematic. This

will often tend to almost magically find distinct functions that are

easier to understand, which then "communicate" with each other via

relatively easier to understand connections between them.

Not Entirely Improbable Example

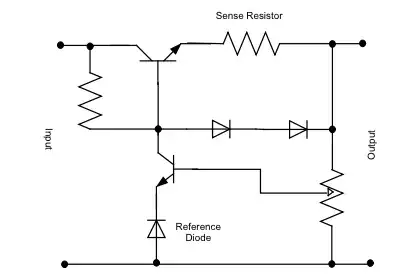

Here's an example of a less readable CE amplifier stage. It's a little more of a wiring diagram than a schematic. See if you can manage to recognize that this is a relatively standard, bootstrapped single BJT stage, CE amplifier:

simulate this circuit – Schematic created using CircuitLab

Here's a more readable example of the same circuit. Here, despite being a bootstrapped design (which is seen a little less often), you can recognize the basic CE topology and begin to pick out the similarities and differences better:

simulate this circuit

Note that I've rid it of the power supply and ground bus wires. Instead, I've simply noted that certain end-points are attached to one or the other of the power suppy (+) rail or ground. For someone wiring this up, it isn't as helpful because they might miss a connection they need. But for someone trying to understand the circuit, those connection-details just get in the way.

Also note that I've carefully arranged the new circuit so that conventional current flows from the top of the schematic downwards towards the bottom of it. The general idea is to imagine this as a kind of "curtain" of electron flow (bottom to top) or positive charges from top to bottom (conventional.) Either way, it's like a force of gravity that causes the curtain to hang from top to bottom.

Flowing through this curtain of top to bottom currents, the signal passes from left to right. This is also very helpful for others trying to understand a circuit.

Combined, these details help orient a reader.

Also, if you imagine that \$C_1\$ and \$C_2\$ are absent from the schematic (left open) and that \$R_6\$ is bypassed (shorted), then this is a very familiar single BJT CE stage found almost everywhere. So this provides some additional guidance or orientation for understanding the circuit. It allows you now to realize that \$C_1\$ acts as an AC-bypass across \$R_4\$ so that the AC gain can be independently set, separately from the DC operating point of the amplifier stage. The only remaining details are to work out what \$C_2\$ and \$R_6\$ are achieving (bootstrapping.)

The original layout above (the confusing one) would greatly hinder the ability to zero in on the bootstrapping aspect (which may, or may not already be familiar.) But at least this means there is very much less to focus on and try and understand, if unfamiliar. (The first schematic would make all of this almost entirely hopeless from the start.)

This may not be the best example, but at least it shows some of why it helps to avoid wires that simply bus power around and why it's important to arrange the schematic with a specific flow of conventional current from top to bottom and for signal to flow from left to right.

More Likely Example Case

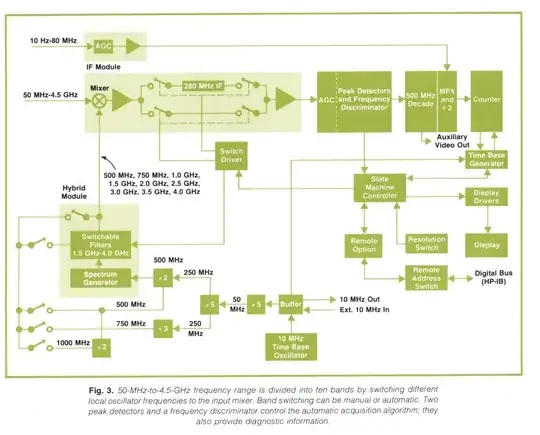

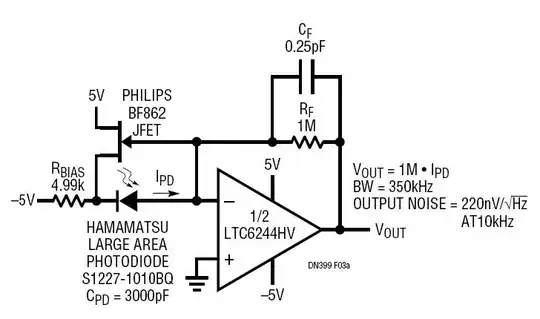

A better example would include a more complex circuit (which as the one for the LM380.) This would help illustrate the knots of circuit groups that can be organized into separate sections (more tightly interwoven within themselves, but communicating to other sections via a sparser set of wires communicating signals.) So I'll end this by including a nicely divided LM380 schematic to illustrate that point:

simulate this circuit

Note that there are individual sections, now isolated as identifiable groups such as current mirrors, long-tailed differential amplifier (here, really, more of a \$\pi\$ type arrangement), and an output stage.

The annotations also help. In fact, if possible it is a good idea to include design-note annotations on your schematic. This helps to draw attention towards the key ideas relating schematic subsections to each other.

Try and imagine what this would have been like to read through had the power supply and ground rails been all connected up with additional wiring and/or with no particular arrangement of current flow on the page.