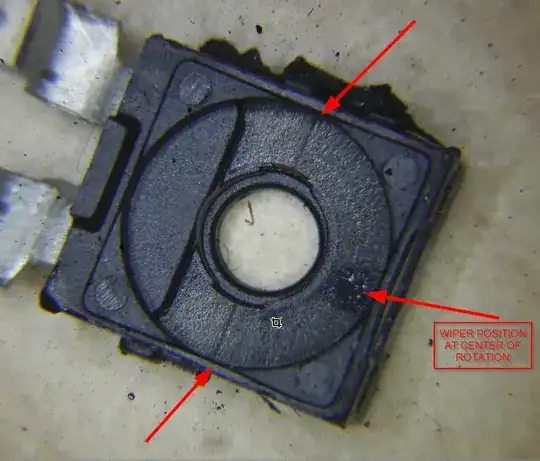

I am trying to use a potentiometer as a voltage divider and am finding that the output voltage deviates from the calculated value as I turn the knob away from the 50% mark. The potentiometer I'm using has a total resistance of 100 kohms and looks like this one:

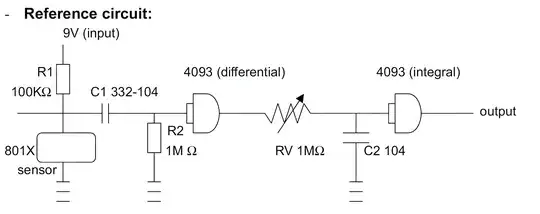

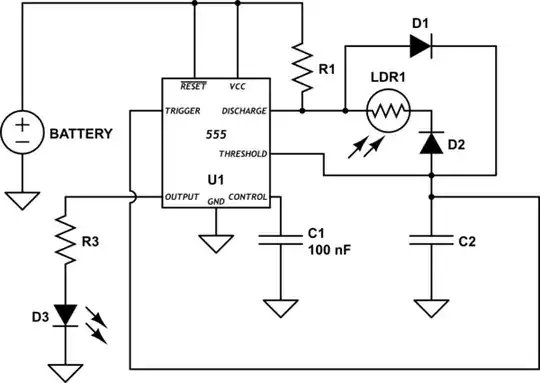

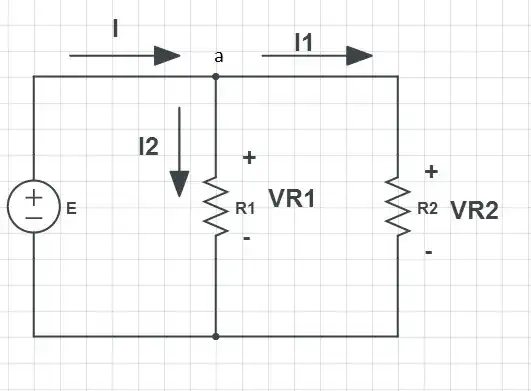

And here is the circuit I am testing:

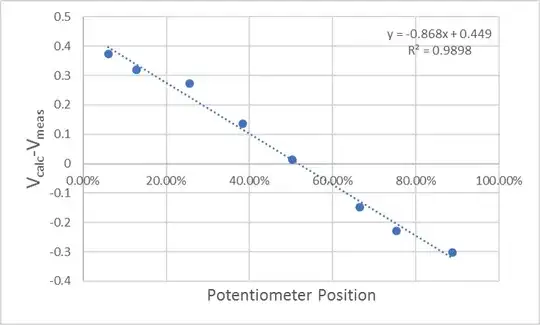

Finally, here is a chart showing the deviation of the calculated output voltage from the measured value as a function of knob position on the potentiometer:

Is this a wiper resistance problem? Any insight would be appreciated.

UPDATE: This is actually incorrect, see next update

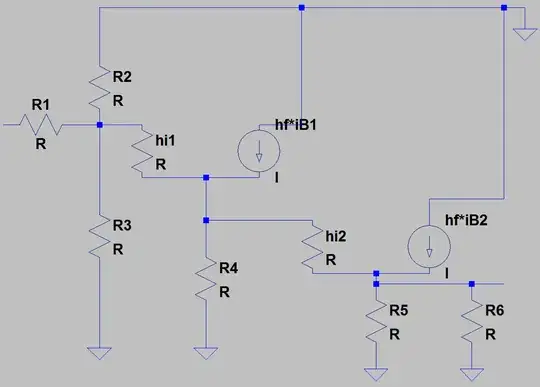

I simulated adding a wiper resistance (Rwiper) in series with the DMM input in LT Spice. I found that a value of Rwiper = 5 kohm essentially eliminated the error in my calculated voltages.

And here is the plot of the difference between measured and calculated voltages:

UPDATE:

Well, back to square one. Turns out I was looking at the wrong column in my spreadsheet when I added the wiper resistance above. When I tried to simulate the circuit again I could not obtain the measured voltages using Rwiper. At any rate, here is a table showing my measured resistances and voltages. Maybe someone out there can figure this out. Driving me nuts!