This looks like it's due to a combination of bad engineering, bad management, and cheap labor.

Circuits don't always perform as expected when first designed. Even experienced designers make mistakes occasionally. Usually these are caught in the first prototypes, then the board respun.

Not all engineers have the experience and skills to get a circuit mostly right the first time, and the discipline to test it properly before committing to production.

Couple that with management that doesn't understand the engineering process, and a junior engineer hired into a position over his head who won't or can't stand up to management. It's exactly those types of managers that hire a junior engineer for such a role in the first place. "After all, it's just engineering, and all engineers are plug-replaceable, so I might as well hire the cheap one right out of school that won't give me all this crap about can't this, and test that."

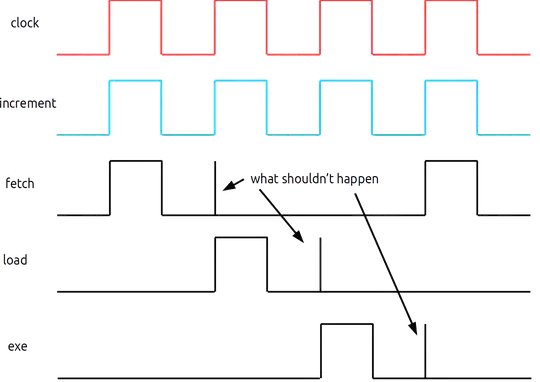

You've got 10,000 populated boards and someone finally discovers that this thing oscillates when the volume knob is turned to 60% and you use one of the wall warts from the last shipment of 5,000 you just received. Your junior engineer doesn't understand what's happening, but determines that the wall warts are within spec. Now you've got a big problem, so you hire a consultant to look over the design and fix it.

The consultant shakes his head, tells you the whole design is a mess. You don't want a new design. After all you already paid for one. You tell the consultant you absolutely need a fix for this design. He comes up with the kludge you see above. You have the same factory in the far east that made the boards rework them. The labor cost is cheap, so it's better than scrapping 10,000 finished boards.

Good engineering is expensive. Bad engineering is even more expensive.