I’m developing a huge project, very cool but very complex, is a “water printer” based on the work of a Japanese artist. I’m an electrical engineer so I’m very good at electronics and software dev, so most of the project is already done, I made a computer controlled interface that can control several solenoid valves at the correct rates to “print” an image using water and gravity, here you can see an example of an early stage of my project simulating the valves with just LEDs.

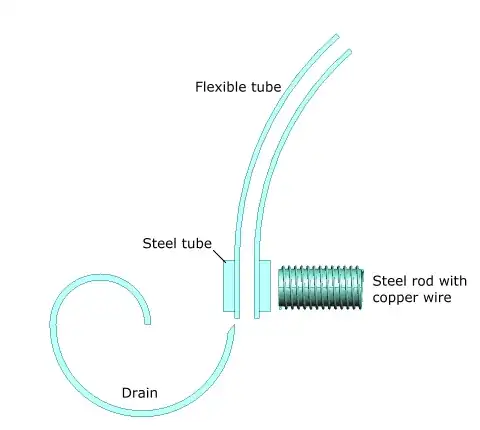

I never worked before with solenoid valves, I bought some on ebay from Hong Kong, but I made I mistake, this kind of valve need a fixed amount of pressure to displace the actuator so they are very slow to close (not good for this project given the fact that I need a droplet), also I just find valves form 1/2’ (which are very big) and for about 10 bucks, taking in consideration that even if they work I will need about 100 of them, I can’t afford 1000 dollar for this.

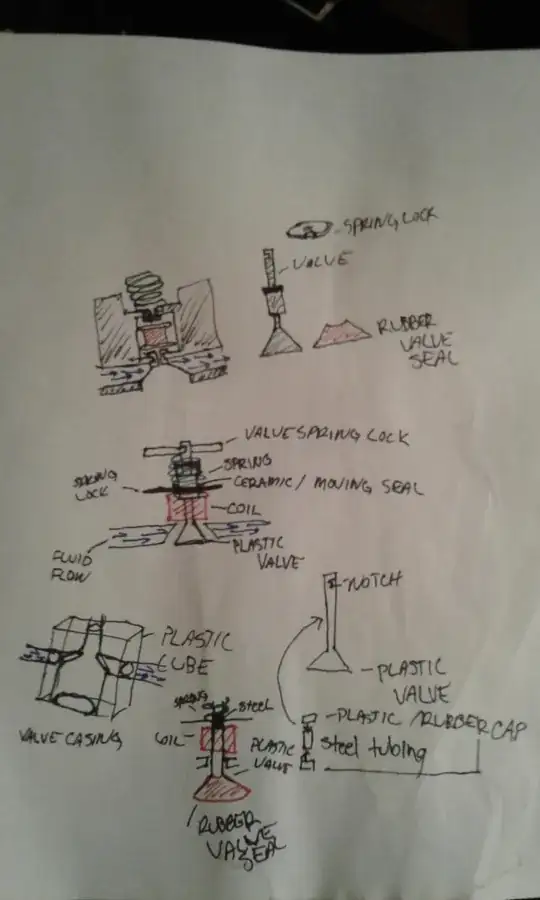

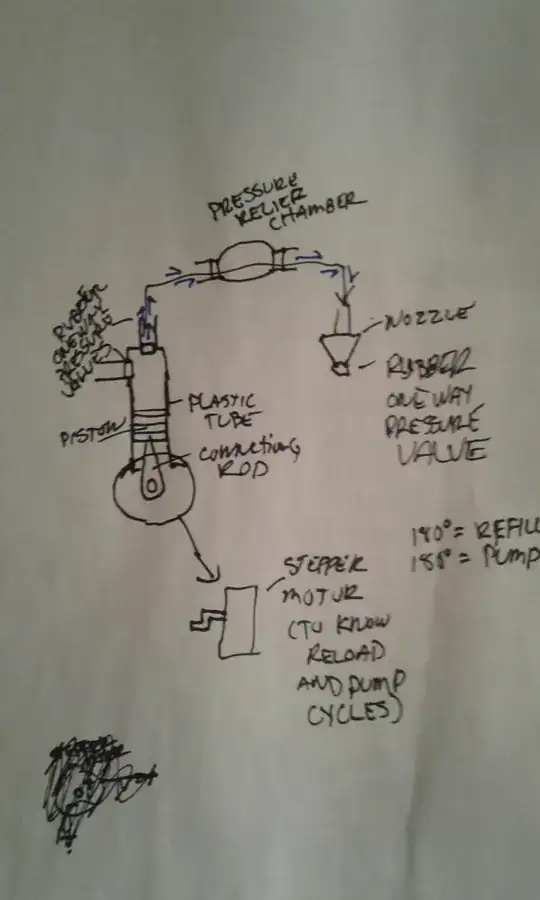

I decided that the only way to solve this is building the valve, but I’m not very good imagining mechanical actuators, so I need the help of creative minds like yours guys. I’m just going to simplify what I want, imagine that you need to control the flow of water of an fish tank pipe using an electric signal, that’s it, what do you think? Let your imagination fly! :)