But for a mechanical strain relief for over stress on users with kids and USB plugs getting torn out, it is excellent.

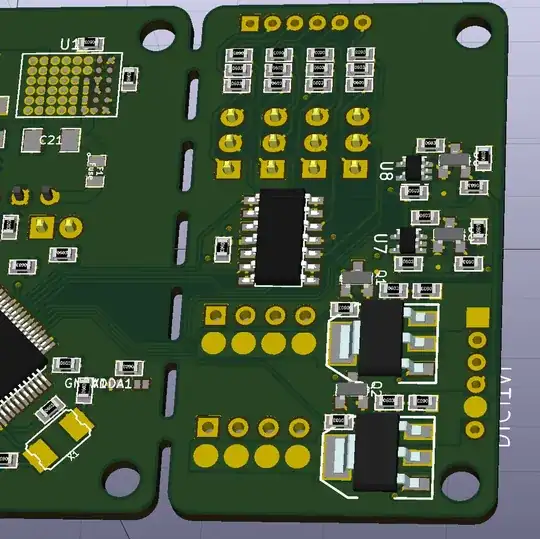

The main board has a good 3 point screw hole mount to eliminate torsional stress on brittle ceramic parts and the breakaway allows more board bending stress to occur at the gap without stress on the ceramic chips. Meaning OK for open board use with bending stress on USB port and no mounting holes for USB area with strain limited by case mounting holes for USB connector.

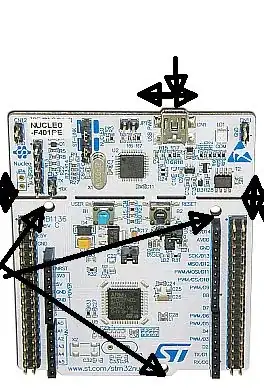

http://ett.co.th/prod2014/NUCLEO-F401RE/NUCLEO-F401RE_3re.jpg

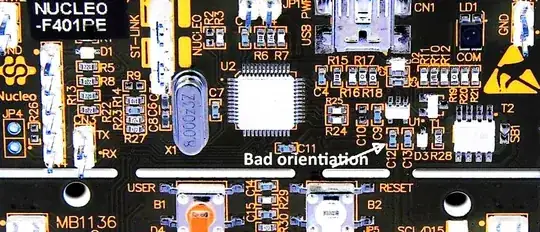

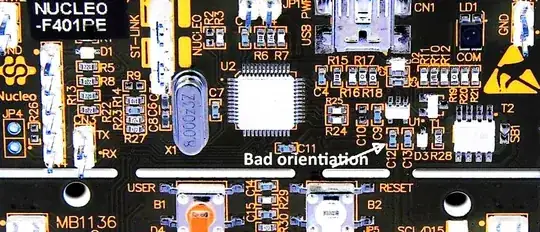

The orientation of the SMD cap near the break tells me it was never intended for a breakaway, rather a stress relief joint with an external USB plug.

Inverse video enhanced enlarged area of link above:

Conclusion

Good mechanical design

Bad Breakaway panel design. * false assumption *

C12 , C13 could crack with normal attempts to snap or shear the break.

- This design would fail DFM for breakaway design rules.

But since I conclude it is a false assumption, to be a breakaway, it is a good design for stress relief.

Break on this area would require a micro-router with copper track Dremel® cleanup.

Reference : 40yrs experience in R&D and contract Manufacturing and many breakaway design flaws from operators and design flaws.

- eg. When I was Eng Mgr of a contract Mfg, C-MAC in Winnipeg, a customer , Honeywell's Avionics division in Phoenix, designed a board we made in volume, a jet engine control board , which experienced occasional cracked Vcc decoupling Ceramic chips in a biscuit panelized large motherboard.

We fixed the flaw by training operators to shear snap boards more carefully, so as to limit board warp and not to make invisible cracks in the HUGE ceramic 10uF caps. Honeywell improved the design in later Rev's.

Orientation and proximity near biscuit breaks are crucial design features among others with V-score preferred or biscuits with many spaced holes in between offset towards PCB inside edge.

ADDED

If you intend to separate and reuse the small board; use any of the following methods

- cut with metal type hack saw blade ( no handle needed) or hand router or exacto knife deep before carefully snapping v-score