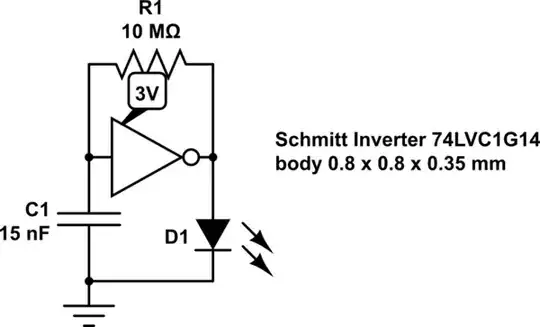

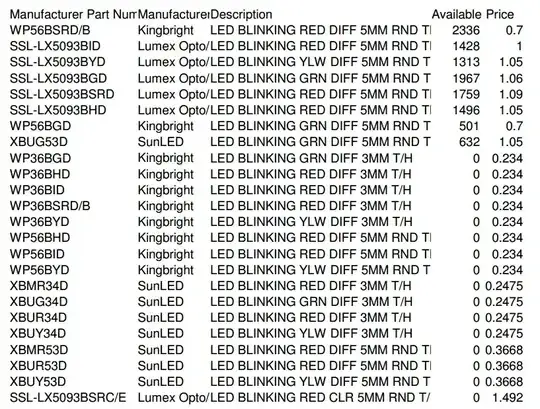

While you could buy a blinking LED as suggested, you are then constrained to the blink rate provided by the supplier.

I'd suggest that the cheapest and most flexible solution overall would be something like an ATTiny13A in an 8 pin SOIC.

Your 5050 LED (If it's RED) has a Vf of about 2.2 V @ 100 mA, so you will need a series resistor to limit the current (a 12 Ohm resistor).

You could (once it's programmed) use 5 of the ATTiny13 pins in parallel to drive the LED with a 100 mA pulse (to ground) and have one pin left (Reset*) to provide an on/off switch/jumper capability.

You could have a single power supply decoupling capacitor, but at very low frequency (I'd run the ATTiny at 128 kHz) it's doubtful you need it. You be able to disable all features in the ATTiny and use the Watchdog Timer to bring you out of power down mode 5 times a second (you'd actually have to wake up the MCU every 4 mS and count to get your 200 mS time). Once awake you can time the pulse width of your LED drive using a timer or register (not much difference in this application).

An ATTIny13 is about $0.60 1 off, a 555 timer about $0.48, but you'd need two to provide 5Hz and then your pulse width for the LED on time ....so the MCU is by far cheaper.

If you are only building a few of these items, the ATTiny85 would be the best choice for ease of programming (direct from the Arduino IDE),though it'll cost you about $1

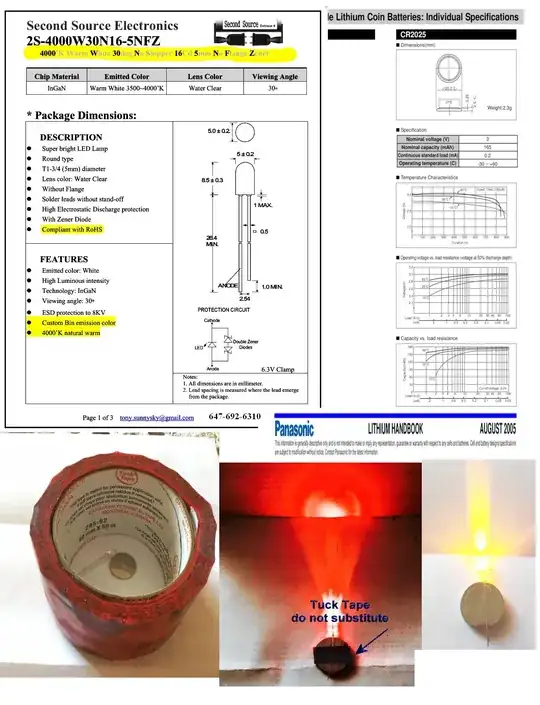

Getting 100 mA from a CR2032. The short answer is that you can't, but you can put a capacitor across the battery and use this to store energy for a larger pulse capability.

This limitation and solution below apply whether you use 2 * 555 or an MCU solution.

The CR2032 does have some useful pulse capability, and probably more than you would think:

This tells us that the output resistance of the battery is about 10 Ohms and that with a 100 Ohm load you'd easily get a short pulse capability of about 29 mA.

This tells us that the output resistance of the battery is about 10 Ohms and that with a 100 Ohm load you'd easily get a short pulse capability of about 29 mA.

The capacitor is charged to the battery terminal voltage and we know that if we have a load of 100 mA that while drawing that current both the battery and the capacitor would supply it. When the voltage drops down to 2.9 V we know that the battery is supplying 29 mA maximum, so the rest must be coming from the capacitor, 71 mA. Since the battery supplies no current initially and 29 mA @ 2.9 V, then we can average the current from the capacitor at 86 mA.

A very approximate calculation would be to consider the load a constant current on the capacitor (it isn't, but it simplifies our calculations) and use:

t = {C x (V0 - V1)} / I

We can use this to find the maximum LED on time that could be supported once we select the maximum capacitance that fits in the form factor.

Since the solution is probably disposable, we need to use small cheap capacitors that will fit within the battery diameter and not be too high. Ceramic and Tantalum capacitors would be too expensive, leaving us with Aluminum Electrolytics.

A reasonable choice might be 2 * 470 uF 4 V Nichicon low leakage, low height capacitors. At 8*5 mm two of them will fit within the battery diameter ...so this might work as an example.

So with 2 * 470 uf and a constant current of 86 mA what is the pulse width that could be driven?

t = (940 * 10^-6 * 0.3) / 86 * 10^-3 = 3.3 mS

And of course if you were to drop the LED pulse current to say 50 mA, you could drive a much longer pulse width or drop one of the capacitors.

t = (940 * 10^-6 * 0.3) / 35 * 10^-3 = 8 mS

The only element we have no details on is the short pulse battery recovery time. This may limit the flash rate, so you'd have to actually try it out on a coin cell battery to see if you can achieve 5 Hz.

Hope this helps.