I'd wish to insert a small 12x33mm PCB into a USB slot multiple times a day. Because of that high number of expected mating cycles, the surface finish of the edge connector should be chosen wisely.

The PCB will draw 2 microamps of current in power-down mode, and up to 8 milliamps at peak levels. And the components are likely to last for over 20 years, so it the PCB.

The contact wear will be caused by spring contact and the wear is sliding.

"Common" surface finish options for increased mating cycles are:

- ENIG - Electroless Nickel, Immersion Gold

- ENEPIG - Electroless Nickel, Electroless Palladium, Immersion Gold

- electrolytic nickel gold - (sulfamate) nickel with hard (or soft) electrolytic (acid) gold layer on top (often 3:1 layer height ratio)

- galvanic gold a.k.a. hard (plated) gold a.k.a. electrolytic gold a.k.a. electroplated gold. This is gold with hardening additives (like cobalt) without the nickel base layer.

The "Blackpad effect" seems possible with hard plated gold and ENIG. So these PCB finishes can only be applied selective not over the complete board, or when applied full board, loose the rework capability.

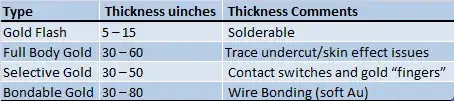

I do need an edge contact connector (a.k.a. "finger") finish mainly for high mating cycling low wear. I do not necessarily need to meet any spec its contact resistance upper limit value. Still having a connection that works, and doesn't do harm to the spring contacts of the USB female connector is sufficient. There is no soldering to be done on these contacts.

Which (sufficient, not the best) surface finish to choose for these contact fingers, and why?