I have an AC single phase motor (120V/60Hz) connected to mains (plus a power resistor in series, and capacitor and voltage controlled resistor in parallel) The motor has a NTC thermistor attached to it. I'd like to know how to design a circuit that uses the thermistor to cut off the AC current when the motor gets too hot.

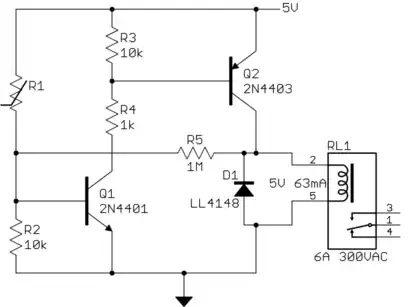

In my research I've read different things about using relays or BJT's but haven't been able to come to a definite solution. My best guess is that I use the thermistor to divide the voltage from a DC source and use that to control a relay. I read here (Relay control of AC motors, handling turn-off kickback) about some problems with just having the relay. So I'd like to know what you'd suggest.

I'd like this solution to fit on a proto board if possible, if that helps with scope.

If it helps, I found that the thermistor is about 8 kOhms when the motor is at room temperature and about 4 kOhms when the motor gets too hot to handle. I don't need you to design the circuit for me but an arrow in the right direction would be grand.

Thank you!