Why are cables only made of round shapes? What is the advantage of it? Why aren't there triangular or quadrilateral or pentagon shapes of cables?

-

13We used 1mm square wire for microwave filter design – Tony Stewart EE75 Jan 03 '17 at 21:24

-

8In high power applications, square copper is used because it can be bolted together. – Optionparty Jan 04 '17 at 03:48

-

4Do an internet search for Copper Bus Bars, they come in all shapes and sizes. – Tyler Jan 04 '17 at 04:05

-

15Not all cables are round. It's just that round cables are cheaper and more resistant to stress (we really like to use curves where stress is a problem - it distributes the load evenly, unlike sharp corners). Why are round cables cheaper? Because cables are drawn, and round dies are more resistant to stress and spread the wire more evenly. And for alternating current, the flow isn't through the whole are of the cable, but just the skin - a round cable is most efficient; this only becomes important for large cables (diameter > ~20mm for 60 Hz current) or high frequencies, though. – Luaan Jan 04 '17 at 13:14

-

Wow, I am impressed. I didn't know much of shapes of cables until now. Shapes are explained nicely below in comments and answers. Definitely +1. – Keno Jan 04 '17 at 18:44

-

1Because shape doesn't matter in most applications, and round wires are the cheapest to get. Where shape matters, you can get wires shaped like you want, at an additional cost. – Dmitry Grigoryev Jan 06 '17 at 08:38

-

1It is an interesting question. In theory, at higher frequencies, all the current is carried in the outermost layer of the wire, and round wires have the smallest circumference for their cross-sectional area. So one wonders whether another shape would carry more current at higher frequencies. – Hot Licks Jan 06 '17 at 12:46

-

2@Luaan, a round cross-section has _less_ skin than any other cross-section. Round is the least desirable shape when skin-effect is a concern, but it costs a _lot_ less to manufacture than any other shape. Google for "litz wire" if you want to know what they use when skin-effect becomes a big problem. – Solomon Slow Jan 06 '17 at 21:15

-

Give it a few years and speaker manufactures will be selling speakers that sound 800% better because they use triangular wires. – user2248702 Jan 07 '17 at 09:32

-

1Bear in mind, a "wire" is a single conductor, while a "cable" is two or more insulated wires wrapped in one jacket. – Lexib0y Jan 08 '17 at 10:50

-

Thanks for the terminology correction Word Boy We were well into this discussion before you set it straight. I wish there were some preliminary editing of the submitted questions to avoid this type of proliferation of misinformation. – FiddyOhm Jan 08 '17 at 20:13

-

1If they were rectangular, we would need to drill a rectangular hole for THT. – Thomas Weller Aug 31 '21 at 18:38

9 Answers

Like Jessica Rabbit- because they are drawn that way.

Wire production involves pulling (drawing) the wire through successively smaller dies (often with annealing in between). The dies are most easily made with round holes (they are typically made from very hard materials such as diamond).

Not all wire is round - rounded rectangular wire is sometimes used in inductors and transformers.

- 376,485

- 21

- 320

- 842

-

8Occasionally hexagonal - at least one loudspeaker drive unit mfgr winds voice coils from hexagonal copper to get a slightly lower impedance in a narrow gap. http://www.morelhifi.com/technology/ Some high current transformer windings are flat copper ribbon. – Jan 03 '17 at 21:22

-

2And of course there are thin copper tape solutions (extreme rectangular) such as those for flat speaker wires. – Jack Creasey Jan 03 '17 at 21:46

-

1If you want to see the variety of what can be done, or even try it yourself, jewelry suppliers sell various alloys drawn in various shapes, as well as actual drawplates with various aperatures. Of course drawing any useful quantity of wire by hand would get old quickly. – Chris Stratton Jan 04 '17 at 19:21

-

11

-

2I doubt wire drawing dies are made from diamond, they're generally only used in grinding. The hardness of the die doesn't really matter as much as its strength; you don't want to abrade anything. For copper wire it's almost certainly tool-steel. – Nick T Jan 05 '17 at 16:35

-

3@NickT For serious production of copper they do seem to use tungsten carbide or PCD (polycrystalline diamond). That was what I was told last time I toured a factory making wire. Apparently single crystal diamond is used for very small wires. A few kg of copper can end up being many km of wire. – Spehro Pefhany Jan 05 '17 at 19:18

When you move away from circular cross sections you run into two significant problems:

First, corners would exert more pressure against adjacent things, and are more likely to result in insulation damage.

Second, for high frequency use the skin current effect would result in higher impedance in a cable with the same cross sectional area but with corners. Further, the greater amount of insulation required to cover that conductor would also change the impedance. While this could be dealt with, we already have a great understanding of the skin effect, impedance, and insulation effect at high frequencies for round conductors that it would be limiting for designers to use alternate configurations without a good reason (such as fitting more copper in a smaller area for efficiency in inductors).

There are many other considerations - wire drawing is already difficult and strenuous, having a circular cross section reduces die contact for a given area of copper. Insulation would increase due to the additional circumference of a triangle or square compared to a circle (again, for the same cross sectional area of copper). When bending or flexing the corners would see more stress, would harden more quickly, and would crack more readily than circular cable.

When discussing cables it becomes even harder to make other cross sections. Imagine taking 10 conductors to make a cable in a triangle. When bent, twisted, or squeezed you'd find the individual wires in the cable moving out of their place and deforming to a more circular shape. How would you keep those wires in place to maintain the desired cable cross section? You could go to a single wire, but then it will be much harder to manage, much less flexible, and more prone to breaking and damage.

- 20,339

- 7

- 59

- 95

-

1Since you talked about skin effect, I'd relate this to the cross section's area, which determines resistance (and ignoring insulation, the ampacity), and use the information that [a circle is the shape of smallest perimeter for a given area](http://math.stackexchange.com/questions/389339/among-all-shapes-with-the-same-area-a-circle-has-the-shortest-perimeter). – Ronan Paixão Jan 04 '17 at 15:22

-

While a cable made of circular strands will have voids which don't directly add strength or current-carrying ability, the voids within the cable allow it to change shape when bent, giving strands on the inside of the bend someplace to go. – supercat Jan 04 '17 at 20:14

-

I wonder if rolling wire onto spools is affected in the same way cans at the supermarket are for the reason why cans are round. – Rob Jan 07 '17 at 11:00

-

@Rob Circular is just cheaper and more convenient. Square cans mean extra alignment (costs) in machines for closing ends for limited space saving. Corned beef and sardines are sold in rounded rectangular prisms to save shipping space, alas you cannot use all standard canopeners to open the tins (forturnately they often they have their own opening means). – KalleMP Jan 07 '17 at 15:26

-

Adam and @supercat, the alternative to round multi conductor cables is usually flat where the alignment of the wires is fixed during manufacture. This gives much better flexibility in one axis and much worse in the other, often an acceptable compromise. Other cable profiles would be rare to find as benefits would be few and hard to justify. For loose bundles they are drawn into flexible conduits or placed in cable ladders. – KalleMP Jan 07 '17 at 15:29

Flexibility

A round cross section allows the wire to flex in any direction equally.

- 11,811

- 31

- 51

-

Well.. I guess it is not an explanation. Otherwise there would be flat wires inside the flat cables. – Eugene Sh. Jan 03 '17 at 21:28

-

1

-

3Flat (ribbon) cables are not required to flex in all directions. Yet they are composed of round wires. – Eugene Sh. Jan 03 '17 at 22:18

-

11@EugeneSh. The wires inside the ribbon cables are stranded, and they need to be able to flex in order to wrap around each other. – tcrosley Jan 03 '17 at 22:23

-

4

-

6@Uwe & EugeneSh. Please read past the first word. You have both given examples of things that flex in one axis while this answer clearly says "any direction". – Samuel Jan 04 '17 at 17:13

-

1@Samuel, your answer is completely valid, but the point being made by the two people you are addressing is that not *all* round wires are used in places where they *need* to flex in all directions. Of course this doesn't invalidate your point; it's not like you said, "Wires which don't need to flex in every direction are not round." – Wildcard Jan 06 '17 at 02:09

-

@Wildcard Sure. There are really two options for an answer here. I can make a list of the possible solutions (which I believe SE looks down upon), or I can add what I believe is the best answer of the possibilities, which I've done. There are many reasons cables are round, as evidenced by the answers here, but I'm just listing one. A secondary point is that because flexibility in any direction is so desirable, round cables are cheaper because of how common they are, so they appear in many situations where the initial reason for their roundness neither adds (or subtracts from) their usefulness. – Samuel Jan 06 '17 at 02:16

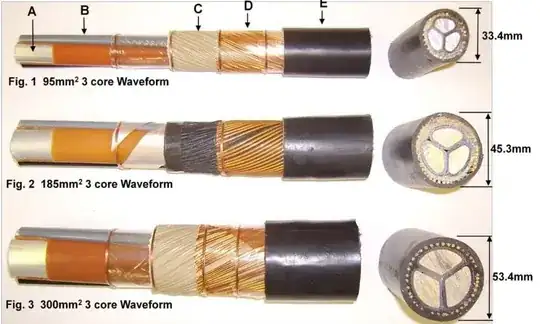

Not strictly copper but for larger cables you do get triangular cores. They tend to use aluminium for larger cores like these.

- 281

- 1

- 4

-

3You get copper cables like that too. E.G. http://www.gulfcable.com/scripts/gulf_htmlshow.php?sID=32 – Peter Green Jan 04 '17 at 14:37

-

3@PeterGreen the cable you posted the cores consist of multiple small round cables bound together. The cores depicted here seem solid? – Tschallacka Jan 05 '17 at 07:41

-

1@Tschallacka Yes, aluminium cables sometimes come with solid (non-stranded) conductor. – Li-aung Yip Jan 15 '17 at 00:18

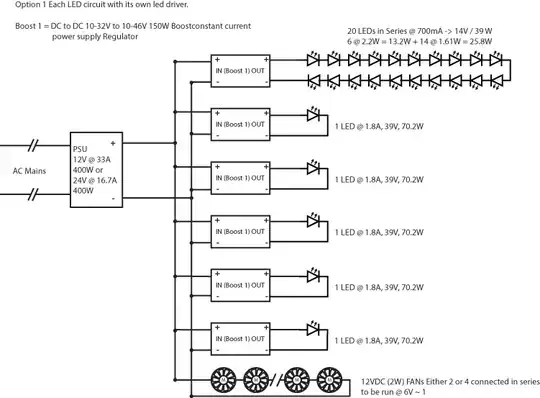

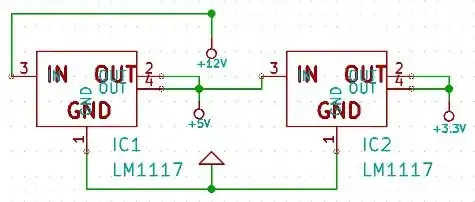

In industry, solid (retangular) metal (usually copper) buss bars are used, generally for high current applications:

...so, not always round.

- 245

- 2

- 9

-

1Good example is also a simple medium current relay: http://www.tech-faq.com/wp-content/uploads/Relay.jpg – Keno Jan 06 '17 at 13:22

-

-

1@Bohemian, flat wires of very small dimensions are found in places where you need flexing in one direction or where vibration isolationis needed. While a bus-bar may be more substantial than a wire there are also flat wires. – KalleMP Jan 07 '17 at 15:35

From a production point it's easily the most simple shape one can go for, which I would presume is the dominant factor in all of this. It's also mechanically favourable if you consider the strain when you start bending things. And if you think about it, its also is the most efficient way to pack as much cross-sectional area (hence conductive material) in a limited space.

- 351

- 2

- 2

-

4Using circular wires is NOT the most efficient way to pack wires. Square or rectangular is more space efficient: http://www.goto-denshi.com/product-square-wire-melit.html – Jack Creasey Jan 03 '17 at 23:10

-

5Keeping the mechanical flaws of rectangular conductors aside. I'll tell you the main flaw with the rectangular wire concept being more efficient: go and do that with insulation and several wires in close proximity to each other in a wiring harness and try to keep all the wires perfectly lined up so that they can touch each other perfectly face to face to achieve this efficiency. What is the most efficient theoretically isn't necessarily the most efficient in a practical scenario. – Bart Plovie Jan 03 '17 at 23:29

-

4Go look at almost any high powered transformer and you will find square/rectangular wire. I do agree that insulated general purpose wire is almost universally round, but that has nothing to do with space efficiency of the form factor of the wire, I'd suggest it's purely physical manufacturing limitations. – Jack Creasey Jan 03 '17 at 23:44

-

3You are considering a very very specific application with very specific needs and constraints, using that methodology one can argue anything. – Bart Plovie Jan 04 '17 at 07:48

-

3As are you, the OP asked why copper cable are ONLY round....and they are not. – Jack Creasey Jan 04 '17 at 15:51

-

1@Jack actually hexagonal would be best. It offers the best ratio of circumference (insulation) to area (conductor) of any tightly-packable shape – Bohemian Jan 07 '17 at 01:28

-

@JackCreasey, I think you're mixing up cables and wires at this point, big difference! – Bart Plovie Jan 08 '17 at 14:50

For low voltage cables (240 V, 440 V) the shape of the conductor isn't critical.

For high voltage cables (3.3kV and above), the voltage stress needs to be controlled so the insulation doesn't break down.

Voltage stress is strongest at sharp corners. So The easiest way to control this is to make everything round.

- 8,931

- 27

- 50

They are not only round. Anyway dies holes are round cause they are easier to make and the most economic. Also round cables are more versatile in some general situations, for example to insert them into corrugated (or not corrugated) pipes, to bend or curve them in little space, for ex. when is needed to connect them to electrical home-office standard outlets etc. So the round section is in general the most used for practical and economic advantages. Anyway the round section is not the only standard. Other shapes are used. For example lastly is spreading the use of adesive flat cables to home or industrial electrical systems: you just attach them to the wall with their adesive and you can putty and paint directly on them without the use of corrugated pipes, without broaching the wall, without plastering. Also flat wires more effectively dissipate the heat produced during their operational phase causes they have a bigger surface exposed to air compared to the section needed for a specific electric load.

- 133

- 5

Due to the skin effect, alternating current tends to travel on the surface of wire. DC through the whole core. A round wire maximizes the cross-section per unit of material used, so it is the most cost effective at providing a given gauge or capacity. It also has the side-effect of providing the most surface area on the surface of the conductor for a given cross-sectional area of the overall wire.

While the wire making die process itself is largely the reason for it's shape, dies could make it in a variety of shapes, but the circular cross section is also the most cost effective.

- 21

- 1

-

2DZee, round wires have the least surface area per amount of material, so it wouldn't help for the skin effect. That's why high voltage transmission uses tubes or spaced out bundles. – regdoug Jan 07 '17 at 07:37

-

1"the most surface area on the surface of the conductor for a given cross-sectional area of the overall wire". This is utterly wrong! It's just the other way around! – LorenzoDonati4Ukraine-OnStrike Jan 08 '17 at 19:36