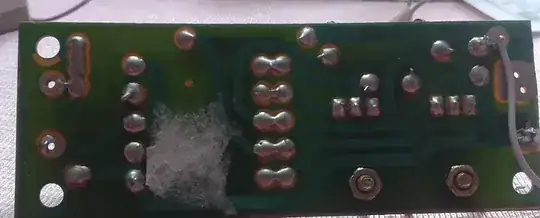

I need to make around 500 or more thermocouples type J 30AWG per year. Currently I am using this thermocouple welder.

The process is quite tedious. I need to strip the wire, sometimes twist the wire, use the pliers to hold the thermocouple, and weld it. The success rate is not 100%; sometimes I fail to weld it into a bead. The machine is around 6-7 years old.

Currently, I am not sure whether should I build a new one (I have no idea how to build a thermocouple welder), get a new thermocouple welder, or to make a fixture that will help to make the process easier (any ideas on the fixture?).