I have a school project where I have to create a haptic feedback wearable with vibrotactile motors. I have gotten the prototype ready which includes motors connected directly to the Raspberry Pi GPIO pins. It all works fine (I am aware of the risks of operating DC motors, without any diodes, on the GPIO pins) but the motors feel kind of weak.

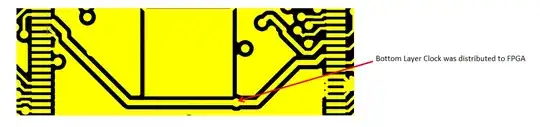

I think this is caused as the motors need to start moving, and at the same time the GPIO voltage/amperage might be not enough. I was searching for a solution and I saw something called Overdrive. The voltage through the motor can be shown in the following image:

The feeling will be quite different then, as the motor will go full force instantly because of the overdrive, and builds off to 3.3V. The motor circuit I have right now is a motor being fed by the GPIO pin itself (digitalWrite HIGH) running through ground.

The circuit I need to build needs to realize the overdrive to make the motors going full force from the start, to make haptic patterns easier to recognize. What has to be done to achieve this?

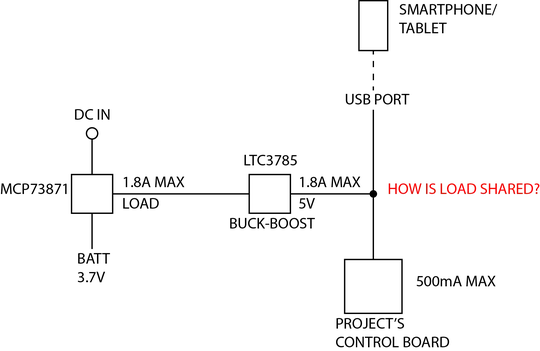

I found this circuit on another page of this stackexchange, which looked like this:

I understood the use of the capacitor, the diodes and the transistor. But this circuit is designed for PWM. I want to use mine with a GPIO pin whereas I can write HIGH or LOW through the circuit. Is it actually possible to generate overdrive so the motors will kick in quickly? What should I consider in the circuit?

Thanks in advance!