I'm working on an isolated 2-sw forward converter.

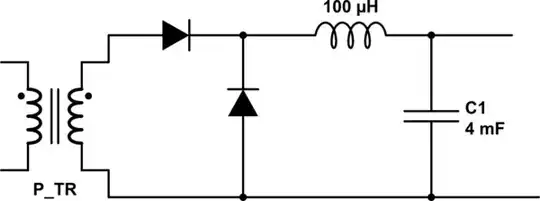

The output section has a toroidal inductor that I've a problem with. Here's how the output section looks like:

simulate this circuit – Schematic created using CircuitLab

The switching frequency is 100kHz and the required value of the output inductor is calculated as about 100uH.

I put a toroidal 100uH inductor (I think it has iron powder core) taken from a broken power supply and left the converter operating under 6A load for half an hour. Then I measured the output inductor's temperature as 50°C which is quite acceptable. So I calculated its \$A_L\$ (from \$L = A_L \cdot N^2\$ of course) as about 95nH.

Then I bought an iron powder core (Part Nr: T130-26K - http://www.pe-coils.com/IPC.htm) having the same dimensions as the other one and calculated its \$A_L\$. Surprisingly, it has the same \$A_L\$ value! I thought that I "accidentally" found the same core, so I wound a toroidal inductor with the same number of turns and using the same dia wire. As expected, I got a 100uH toroidal inductor. No problem until here.

The problem is this: If I use my hand-wound inductor, and under full load, it gets as hot as 95°C! How can it be? They both have the same wire thickness, the same inductance and cores with the same \$A_L\$ values. But where does that temperature performance comes from?

More funniness: if I use my hand-wound inductor, I get %87 efficiency; but if I use the other one, I get %92!

I measured Q values of both with a calibrated LCR meter: My hand-wound has 2.4 but the other one has 1.8. So, what can be the thing behind this issue? What should I do?

[SOLVED] EDIT:

I've experienced that it really comes from core losses. The one with model number of T130-26K is a quite lossy one. So I purchased some toroidal inductors from Mouser and tested each under the same conditions. Finally, one beat them all in terms of thermal and electrical performance. For the ones who are interested, it is 2300LL-101-V-RC from Bourns.

PS: Is there a way to close or flag this question as "answered" or something like that?