I used to work at this electronics assembly plant in Arizona, and the machines there used reels of SMT parts that were like a bucketed plastic ribbon with a peel-off plastic seal. I don't know what those are called; most of them held tiny pieces of the basic elements of circuitry. Occasionally though I saw some moderately sized BGA chips and the like, eg. Xilinx chips that came in these ribbons as well. I'm curious if Intel sells ribbons like that filled with 6700K chips or something, probably to Dell or some other manufacturer. How about AMD selling ribbons of say G-Series SOCs, or any other massive chips or parts that are sold in literal reels?

-

3I think what you are asking about is called an "embossed carrier tape." These tapes can be (and often are) placed on reels. – jonk Nov 10 '16 at 00:17

-

Try googling: http://smallbusiness.chron.com/boxed-processor-vs-tray-processor-43774.html – Voltage Spike Nov 10 '16 at 00:27

-

3I've received some large parts (Atmel FPGAs, I think) in plastic trays. I suspect that larger ICs would be difficult to handle in tape-and-reel packaging. – Peter Bennett Nov 10 '16 at 00:34

2 Answers

-

4I think that only socketed CPUs are shipped this way. The soldered ones (BGA) need to be in carrier tape in order to feed them to the assembly line. – Agent_L Nov 10 '16 at 13:15

-

Yes the balls need better protection from environmental stress ,) for reduced solder defect rates in high volume. – Tony Stewart EE75 Nov 10 '16 at 15:00

-

5@Agent_L Not true, I think. Pick and place can use waffle trays, or feed slots - not sure how the trays are reloaded. Been a while since I observed this. – Sean Houlihane Nov 10 '16 at 15:37

-

1

-

I meant on the PnP machine, after placing 16/21 devices, how is the next later of a stack exposed? – Sean Houlihane Nov 10 '16 at 15:49

-

@SeanHoulihane That's the job of the SMT machine operator. They typically load one tray at a time and swap them out when empty. – TimH - Codidact Nov 10 '16 at 23:32

-

@TimH As the trays on the picture contain merely 21 CPUs, it would be quite frantic job, not unlike Charlie Chaplin in "Modern Times"! https://www.youtube.com/watch?v=DfGs2Y5WJ14 – Agent_L Nov 11 '16 at 13:06

-

2I used to be an SMT machine operator. No pick and place machine can build 21 motherboards that fast... unless it's doing it wrong. I'm sure the very high volume overseas places have some automated way to swap matrix trays, but it's not at all unreasonable for a person to do it among their other tasks. – TimH - Codidact Nov 11 '16 at 18:43

yes

14.6 Handling: Shipping Media 14.6.1 Mid-temperature Thin Matrix Tray The BGA packages are shipped in either a tape and reel or a mid-temperature thin matrix tray that complies to the JEDEC standards. Typically, JEDEC trays have the same ‘x’ and ‘y’ outer dimen- sions and are easily stacked for storage and manufacturing. For tray dimensions please refer to Chapter 10 of this data book. The JEDEC style shipping trays are returnable to Intel for reuse. Chap- ter 10 contains detailed information on the return addresses for the different types of shipping trays. Intel will pay all shipping costs associated with the return.

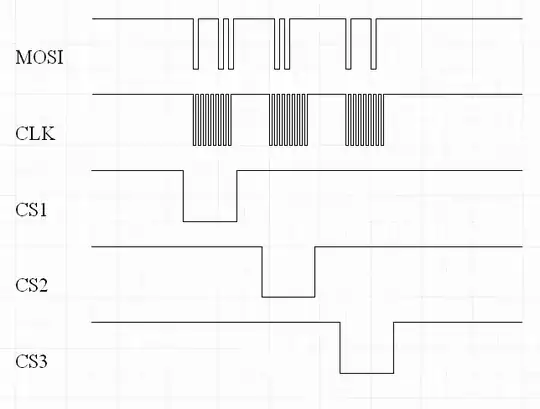

14.6.2 Tape and Reel Tape and reel handling is engineered to contain and protect surface mount components in embossed semi-conductive PVC or polystyrene carrier tapes to aid the high speed board mounting operations foundinmanyhighvolumeboardoperations. TheBGApackagesareshippedfromIntelinacarrier tape made of antistatic treated plastic. It offers exceptional strength and stability over extended time and wide temperature variations, while at the same time maintaining flexibility for use in automated equipment. The cover tape used is heat sealable, transparent, and antistatic. The loaded carrier tapes will be wound onto a plastic reel. The carrier tape dimensions meet the EIA standards. The tape and reel packaging standards offered by Intel for many of the PBGA/HL-PBGA packages meet the EIA standards, ie, EIA 481-1, 481-2, and 481-3.

However, there are some products

shipped from Intel in tape and reel that have a package orientation in the tape that is different from the EIA standards. It is advisable that the user of Intel BGA products obtain a product data sheet that shows the tape and reel shipping details to insure the correct cavity orientation is understood.

- 1

- 3

- 54

- 182

-

2This shows that Intel produces *some* BGA components that are supplied on reels, but it does not necessarily follow that any of them are CPUs (which are typically larger than most other components and would therefore be harder to package on a reel). – Periata Breatta Nov 11 '16 at 03:40

-

This included all large chips in BGA format. Did you read the link? PBGA 544 is 27mm square ... but correct ,not all CPU's come in BGA format. – Tony Stewart EE75 Nov 11 '16 at 03:57

-

What Intel CPUs come in PBGA 544 packaging? Intel CPUs usually have over 1000 pins/balls. – Ross Ridge Nov 11 '16 at 06:42

-

@RossRidge Very old ones. The PDF referenced is from Intel's "2000 Packaging Databook" -- it's 16 years old. – Nov 11 '16 at 07:29