Hi I have seen a design for some LED strip lighting that is very simple to understand but am really looking for the various components so that I can replicate it. It seems that I don't know the right keywords for a successful google search so if you could translate it into the right components I would be grateful.

The wardrobe shelving is cantilevered off the wall. The system comprises of metal wall profiles and metal shelf brackets that hang off this and attach to the shelves.

Now here's the cool bit.

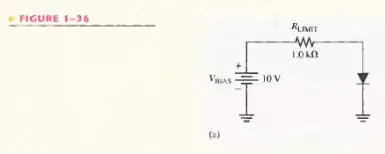

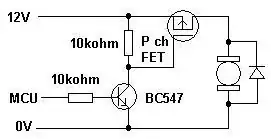

The wall profile has an electrical dual contact strip running the entire length of the profile - about 2meters - this is connected to a 12V transformer to drop the mains voltage - this is no more than 1-2mm thick and 8mm wide:

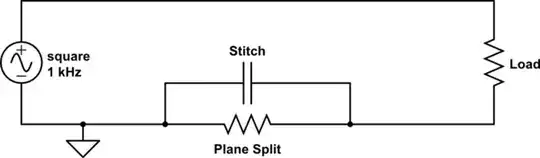

The shelf bracket then has what looks like a strip of flexible circuit board with adhesive backing and a pair of electrical contacts at both ends. The far end contacts look like they are sprung prouder - almost small ball switches on an LED strip - so that when you insert the bracket into the wall profile, they get a good connection:

There is a similar connection on the side of the shelf itself so when it is attached to the bracket you get a good connection as well:

The LED's are then wired normally by coring through the shelf and routing a channel for the LED profile:

The LED's are then wired normally by coring through the shelf and routing a channel for the LED profile:

This design means that if you need to change the configuration of the shelf you don;t need to do any re-wiring.

So the components I'm looking for is:

- The long contact strip - possibly some sort of dual silver alloy strip?

- The slim pair of contact terminals

- The ball switch connectors for the shelving.

I hope this make sense.

Thank you