Let's start with the resolution of the rotary encoder. 13 Bits, provides a rotary resolution of 8192 angular positions (not 8191 - a minor point for sure). This means the rotary encoder, if properly utilized) can resolve 0.044 degrees of rotation of its shaft. In more conventional angular measurement terms that's 2.6 arc minutes of angular displacement. ("arc minutes" is a term used to describe angular displacement to distinguish it from the units of common "minutes" of time.) There is no potentiometer on the face of Earth which can match, meet, or exceed this resolution.

The best potentiometers available for this type of application are called "instrumentation potentiometers" or "precision potentiometers". They are a class quite apart from the type we buy from DigiKey and Mouser. They are typically custom made to order and to specification. There are not many manufactured anymore due to the encroachment of rotary encoders into the applications precision pots were traditionally used in.

There were, in fact, 360 degree (and wider) precision pots. But they were only meant to run in one direction, not in continuous rotary rotation. They used a spiral track with a spring-loaded wiper. A sort of mini multi-turn pot with a fractional second spiral. I digress.

Precision pots were "precision" for several reasons. First, they utilized a knife-edge (wedge-shaped) wiper which provided the fine resolution along the main resistive element. Second, the resistive element was very fine grain, homogeneous material. Indeed, plastic type resistive elements were the best available towards the end of the heyday of the precision pots. Third, the resistance element was mechanically ground to the level of specified perfection in a closed loop fixture. This fixture measured the resistive division ratio between the elements end points and the wiper pick-off point for a given point of angular displacement around its arc, and ground away part of the element automatically to achieve a specified ratio at that point. This operation guaranteed the linearity of the pot. The more points you specified, the more expensive the pot. (And they could cost several hundred dollars apiece back in the 70's and 80's when I worked with these.) You could also specify non-linear "tapers" of various contours thanks to this grinding process. Fourth, the whole assembly was made with great care & precision - special bearings for the shaft, machined (not stamped or molded) case, carefully machined shaft, polished (not sharpened) knife-edge for the wiper, total support for the resistance element, etc., etc... Again, I digress.

Your concerns:

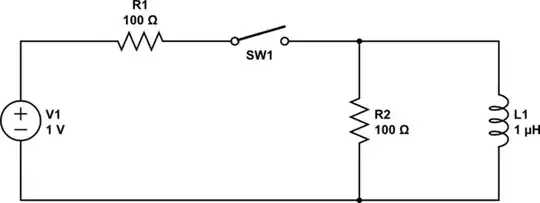

APPROACH: All wrong. 16 bits, or 13 bits, of ADC resolution will not have one "bit" of effect on the resolution of any ordinary (non-instrumentation) potentiometer's inherent ability to resolve small angular differences. Ordinary pots are simply not made to provide this type of resolution. The shafts are very loosely mounted, so there is a lot of slop and hysteresis with relationship to the wiper and the resistive element. And the element itself is very non-linear in these pots. You will need an angular displacement jig to test your candidate pot to see if you can achieve the required resolution with your candidate pots. There fixtures can be purchased from machine shop tool suppliers (even Harbor Freight sold them and maybe still do). Jig up your candidate pot to this fixture and exercise it using a simple voltage divider hook-up with a precision DVM in voltage mode. I doubt you will get better than 1 degree of useable resolution. "Useable" meaning repeatable as you move the wiper away from the specific angular position and then back again after various trial displacements in both directions (CW & CCW).

PLASTIC ELEMENT - Yes, this is likely the best path to follow. Wire-wound types have inherent cogging due to the wire ridges.

LINEARITY - Linearity is not resolution! Plus, there are many definitions of linearity and an equal number of ways to apply the quoted linearity specifications. There are many fine write-ups on the differences between resolution, precision and linearity available on the Internet. Linearity is probably important in your application. Nevertheless, it is quite a different parameter from resolution. Not to mention there are all sorts of specmanship tricks played when stating the linearity of devices such as potentiometers.

FULL-360-ROTATION - This will be a real challenge. If you are reduced to mechanically altering a stock potentiometer to achieve this characteristic, you will probably be better served directing your efforts to modifying an available rotary encoder to fit into your application.

If you search on Ebay for "Instrumentation Potentiometer", you will find a few examples of the type of pot I described above, mixed in with many more conventional "adjustment" pots. The instrumentation type were generally made by small companies with now-unfamiliar names. If you decide to use a potentiometer, get one of these.