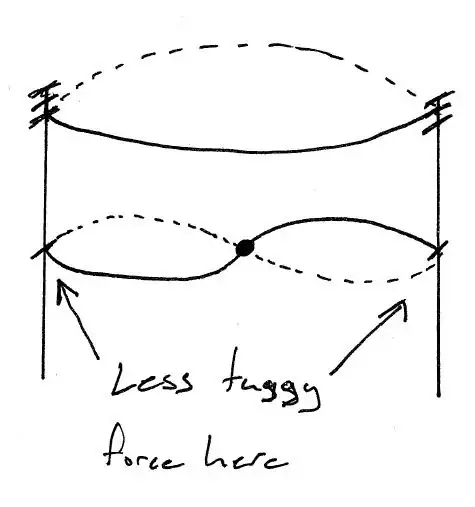

Yesterday I saw what look like weights hanging from a cable between utility poles. This was in northeast Arizona on Route 60 between Show Low and Springerville. Here is a picture of a whole span:

The white blobs are the weights. Here is a closeup of a single weight:

They appear to be just concrete blocks with no dashpot or any other apparent way to dissipate power. These weights seem to be at 1/4 and 3/4 of each span, which would be the nodes of the first harmonic standing wave. They would add inertia and affect the frequency, but is that really their purpose? I can guess some possibilities, but I'd like to hear what these things are for from someone that actually knows.

Due to being a single cable, it must be for communications, not power, but I'm guessing that doesn't matter.

Added

Sorry, I added this note earier, but apparently somehow aborted the editor so that it wasn't posted.

To answer PlasmaHH's question, yes, these were on just about every span. The bottom of the cable was quite high, and a little lower didn't look like it would have been any problem. The bushes you see in the first picture are well in front of the cable. There is a lot of clearance below the actual cable. Even if there was a tall bush there, there would still be a lot of clearance.