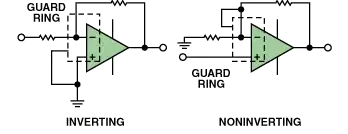

I have read here and there some articles about pcb guard trace/ring. But none of them discussed how to correctly implent it. What I could find were some pictures and comparison that cant help me at the moment!

What I would like to know is how can I make the following circuit more current-leakage proof (In design case - I know that PCB material and SIR plays a big rule).

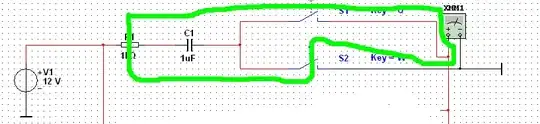

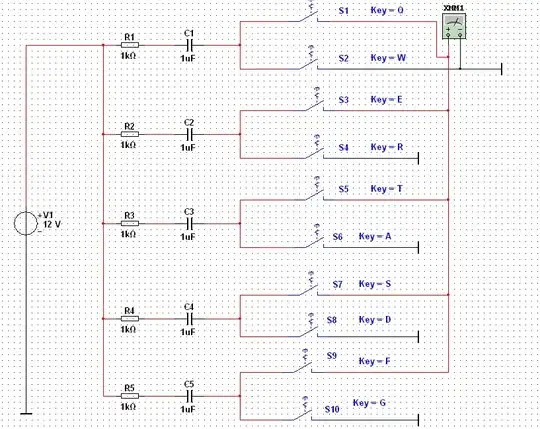

The circuit will supply up to 30V through resistors and each resistor is connected to capacitor. Each Capacitor is then connected to a switch matrix and finally single output from switch matrix is connected to a picoammeter to measure the leakage current of the capacitors.

I am wondering if I should care about leakage current in the circuit or not! If so, how can I improve it?

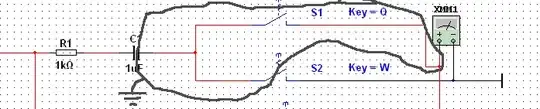

This is my test circuit:

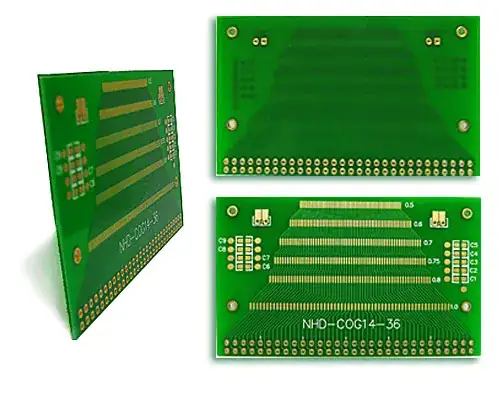

I am thinking of connecting the capacitors just by wire into the circuit, that is one pin of capacitor soldered to by a wire in the little circuit I designed, and the other pin also with a wire soldered to BNC shield that goes to picoammeter and is in common with voltage source (SMU)