The long story short:

Is there any chance that an asynchronous motor with a run (or start?) capacitor fails to run backwards when the capacitor ages and loses a significant portion of its rated capacitance?

The somewhat longer story:

An asynchronous motor using a motor capacitor within a single-phase device is controlled by two triacs. The motor itself has three wires, let's call them L1, L2 and N. There's a capacitor between L1 and L2. The two triacs power either L1 or L2 and thereby allow forward or backward rotation of the motor - at least that's what I'm assuming.

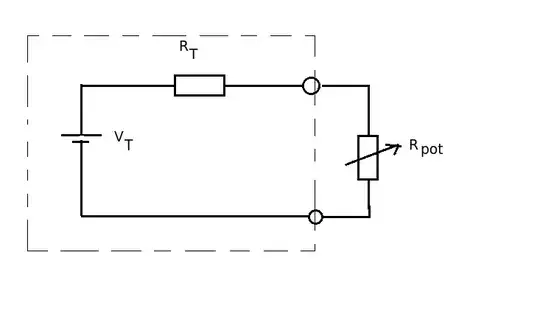

Simplified schematic (switch symbols are really triacs):

C is labeled with 4 µF, but it tests out around 2.2 µF (checked by using a RC network with a 100 Ω resistor and finding the corner frequency with a scope and a function generator - in lack of a DMM with a C range...). So yes, C is indeed bad and it's a good idea to replace it... As long as that's in accordance with what I assume concerning the direction of the motor...

Sometimes, it seems that the motor runs forward when it should be running backward, and my guess is that this may be caused by a low capacitance in the motor's run capacitor.

The even longer story, with some background info:

I'm in the process of troubleshooting my dishwasher. My particular model has one pump motor with two wheels. When it runs forward, it pumps water into the interior, happily splish-splashing and rinsing the dishes. When it runs backwards, it pumps the water out of the dishwasher and into the sewer. After having watched it work and fail for a while now, I get the feeling that sometimes, the motor fails to run in the "dump" direction and keeps moving in the "clean" direction, often in a step of the program when it switches quite fast from "clean" (forward) to "dump" (backward). Then, some blinking LEDs on the panel say that something has failed and it stops working. The blink pattern is not in the user's manual, and it's different from other service error messages (like "water in the bottom, micro-switch above floating styrofoam 'brick' has detected leakage", and I made sure there's no leak). I can rule out pretty much everything else, and the only remaining explanation for the problem is the motor's failure to run in reverse direction (dump) every once in a while. It seems like the level switch still tells the controller that water is present (and there is), when the controller assumes that the pump should have dumped the water and, as a consequence, runs into a time-out. Is there any chance that replacing the motor's run capacitor will fix the problem?

Yes, the motivation of this question is that I'm trying to fix a household appliance. But... Asynchronous motors on single-phase systems with motor capacitors are a very common occurrence, and the question is really with a quite general focus... Once the elliptical field created by the capacitor becomes too narrow, couldn't it be that the motor starts off in the wrong direction? Even more so when it's maybe not a run capacitor but a start capacitor? I might still edit info about my particular make and model of dishwasher into the question at a later point, but as it stands, the question is relevant for any equipment with a motor capacitor and a motor that should be able to run forward and backward.

Once, I had to replace a capacitor next to the motor in a washing machine, but there, the problem was not the direction. It just didn't have enough torque once the laundry got wet and heavy in the drum. Here, the pump's torque still seems to be OK, but it appears it sometimes fails to start in the right direction...