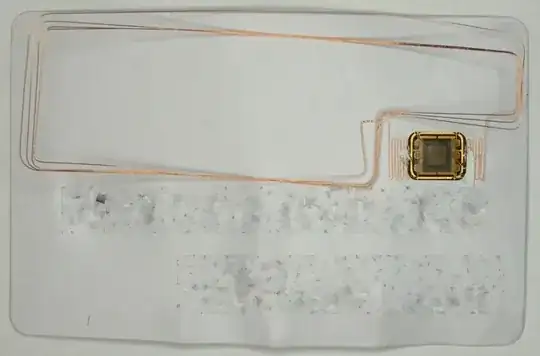

This image is from this post which shows MasterCard plastic card being dissolved in acetone to have the circuitry extracted for further analysis (TL;DR further analysis failed because of chip protective features). Wires are a bit off because acetone made them unbind from the plastic.

Note the area close to the chip - two wires approach the chip and each of them follows a "snake" pattern - down, then up, then down, then up again, that repeats at least four times.

What's the purpose of this "snake" pattern?