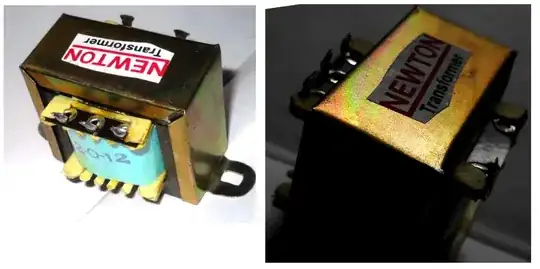

I've seen many times, on metallic objects, a kind of insulator layer is given (I've tested its resistance with multimeter and it shows infinite ohms).

The layer is greenish-gold in overall color, but have colored patches that may vary from red to green.

It is seen on small transformers(above image), switches, fan-regulators, etc.

The layer change its color, and colored-bands shift their place when the parts get heated.

Now , what is the identity of this golden insulator? What is its resistivity and other characteristics?

And also, what is the identity of another, reddish-colored insulator used in electromagnetic coils? also, what is its resistivity and other characterisics