There are two important numbers that have to do with your question.

The first is "Worst Case Scenario": In the absolute worst case, one 2k resistor with 5% will be either 2.1k or 1.9k. One resistor of 1k 5% will be 1.05k or 0.95k, added together this comes to either 2.1k or 1.9k. So in the worst case, in series, a bunch of resistors with the same tollerance will always retain their tollerance over the total value and be just as good as one big one.

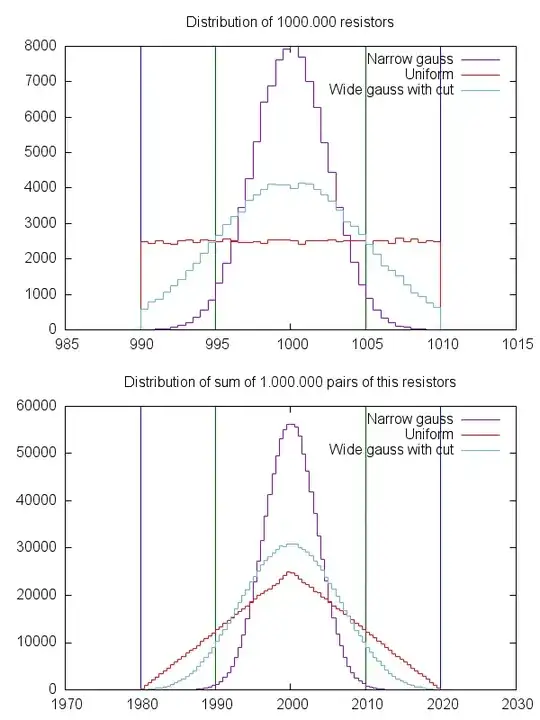

The other important number is the law of large numbers. If you have 1000 resistors that have an ideal target value and are specified with an absolute maximum error of 5%, of course it's very likely that quite a few of those will be very close to the target value and that the number of resistors with too high a value is about as high as the number with a lower value. The production process for components like resistors falls under a natural statistical process, so it's extremely likely the resulting resistors in a large batch across multiple productions yield what is called a gaussian curve. Such a curve is symetrical around the "desired" value and the manufacturer will try to get that "desired" value to be the value he sells the resistors as, for statistical yield reasons. So you can make an assumption that if you buy 100 resistors, you too get a gaussian distribution. Actually, that may not be the exact case, with resistors a large enough number may have to be 10's of thousands to get a real gaussian distribution. But the assumption is more valid than that all will be off by the worst case in the same direction (all with -5%, or all with +5%)

That's all well and nice, but what does it mean? It means that if you have 10 resistors of 200 Ohms at 5% in series, it's reasonably likely that one will be 201 Ohm, another 199 Ohm, another will be 204 Ohm, yet another will be 191 Ohm, etc etc, and all those "too low" and "too high" values compensate each other and it becomes, suddenly, a big 2k chain with a much better accuracy, through the law of large numbers.

Again, this is only in the specific case of the same value resistors in series. While different values in series are also likely to become more accurate on average, the degree to which this happens or how likely it is, is hard to express correctly without knowing the exact use-case and exact-values.

So, it is, at the least, not at all harmful to place many resistors of same value in series, and usually it gives a much better result. Combine that with the fact that manufacturing a huge amount of boards with just 3 different components is much cheaper than with 30 different components and you often see designs with only 1k and 10k (or maybe 100 Ohm and 100k as well)resistos in cheap, high-volume-production trinkets, where any other value is a combination of the two.