Besides the impedance mentioned in other answers: Because they don't need to, or in other words there is not much market demand.

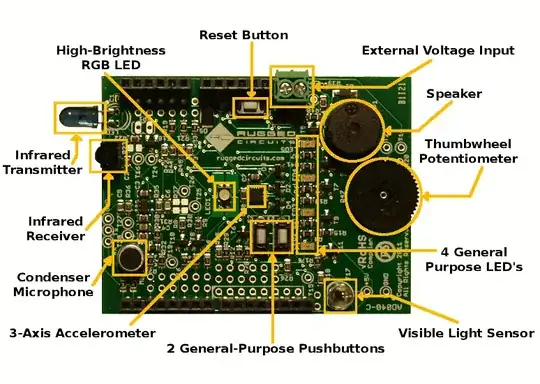

I am mostly referring to items like the one you showed an image of. They are mostly (if for some not exclusively) found in lab or prototyping environments where quality and serviceability is valued more than size. And if you opened up the bias-tee you showed there, you will see that for the 100 bucks it costs it already is pretty small and has quite a range (up to 12GHz) it has to work with.

As andy said, impedance is quite much about physical relationships of conductors to each other, not only in coax but also on the pcb and to a degree with the components.

Having more wiggle room there for the lab grade components is much more important than having them in the smallest size possible. Also for certain price margins you probably want to be able to replace the fuse/TVS/whatever protection blew inside it instead of buying a new one if you mishandled it.

So from that also follows that for this kind of devices, UFL coax is nonsense because it doesn't gain you anything.

If you look around however in modern consumer hardware then you see lots of tiny UFL coax (about every wifi enabled laptop or router these days uses them) but there you don't have the necessity to be useful in a wide band and it only matters if you match the characteristics in a very narrow band.