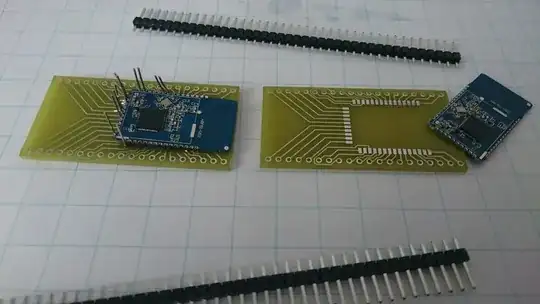

I have made a costum PCB with components and a WT51822-S2 bluetooth module. After testing, there seems to be a low percentage of modules that have a fault in them. Since they are SMD modules, with connections on the sides, its hard to desolder them if faulty. They are soldered on easily with a normal solderin iron but desoldering, thats a whole other thing.

Is there a way to test SMD modules without actually soldering them on the pcb? I have tried pressing them on (with force and duck tape) but some pins have contact, others dont. I have also made a brakeout board for testing, but it still requiers soldering.

what to do?