I use Memory Protection Devices BK-913 CR2032 Through hole battery retainer.

I use Adafruit's CR2032 PCB footprint, which is almost identical to the recommended footprint in the datasheet for the retainer. It is has a square 4x4 mm center pad defined as negative. Around the center pad is a 15.24 mm circle defined as "no solder mask".

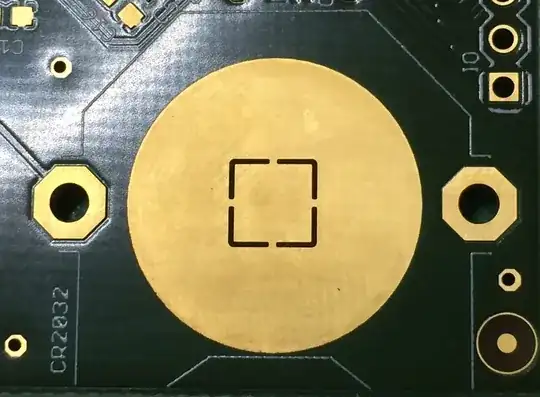

When the PCB is manufactured it looks like this:

Is the square center pad and the surrounding circle electrically connected? If I understand the footprint correctly, they should not be? But the little breaks in the black square surrounding the center pad suggests that they are connected anyway?

I have experienced some problems with this footprint, the connection with the battery sometimes fails. I have to readjust the battery, and some batteries only works if halfway inserted into the retainer. Not very reliable.

It worked perfectly with the batteries I had, but when I got a new batch of the same batteries (same manufacturer, same supplier etc.), they are extremely difficult to make proper contact in the retainer. I guess the batteries from the new batch are a tiiiiny bit different physically..?!

Are there any best practices for footprint design for coin cell battery retainers? For example, I have noticed that the pad under the battery retainer on the Texas Instruments SensorTag looks like this:

What is the reason for this? Are the little solder dots there to help make better contact with the battery?

How can I modify my footprint to be more reliable?