I need some advice on the circuit I plan on building.

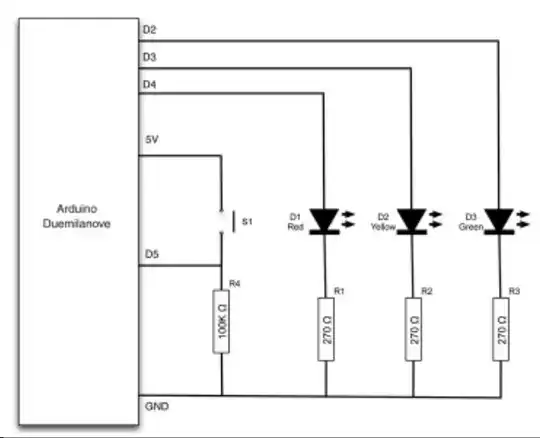

This circuit is to run any high current (Max. 100amps) device in my car. I want to use a high side MOSFET to supply power to any field device. An Arduino will be used to provide a PWM signal (PWM_Out1). The Arduino will also be used to read the current through the shunt R23. INA169 is used to amplify the shunt signal and provide it to the Arduino via AI1. DI1 is also run back to the Arduino and it provides the status of the fuse F1. D4 is just used as an indicator if the fet is on. D10 id my flyback diode. TP1 Jumper is used just to trigger the fet in the field for testing purposes. I used two NPN transistors to have the same logic from the fet that the Arduino provides. D7 is used to limit Vgs voltage to 12v The 24v supply is being provided by a buck/boost circuit (still working on that).

I am definitely not an engineer but I have done a lot of reading over the last few days.

Any comments are welcome.

OK, I changed the circuit to fix some of the issues. Now it seems like there is an issue when the fuses blow, current id drawn through the Vgs zener. In the case below, if the fet is being told to conduct and the fuse blows, my blown fuse indicator still remains high. Any idea how to resolve this? My blown fuse indicator would get connected between the 1k resistor and the 5.1v zener diode.

Here is the revised circuit now. Just trying to figure out the feedback through the fet when its told to conduct and the fuse is blown. My blown fuse indicator @D1 still remains high in this condition.