No. That's not a reliable ESD solution at all.

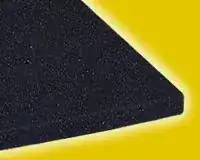

Reason #1 - nothing ensures that the pins stay in contact with the aluminum. Mechanical jostling can cause the pin to work back and forth relative to the styrofoam, and in the process push the aluminum back. You probably will have some contact at some point on any given pin, but if the chip has be thus 'protected' during a lot of handling, don't count on it.

Reason #2 - at best, this would ensure that each pin was at the same potential, so you wouldn't see any large voltages on the die due to fields or discharges at the pins. However, there is no shielding of the device. For proper ESD protection you essentially want to create a little Faraday cage around the device. With the aluminum-on-foam setup, a strong field, or a fast changing field, could introduce voltage gradient between the die and the pins.

That said,

The types of devices you typically see protected this way aren't usually all that sensitive. 74xx series chips are less sensitive than, say, a CPU. If the device is more complex than a medium-scale integration device like a 74xx, you should get static-shielding bags.