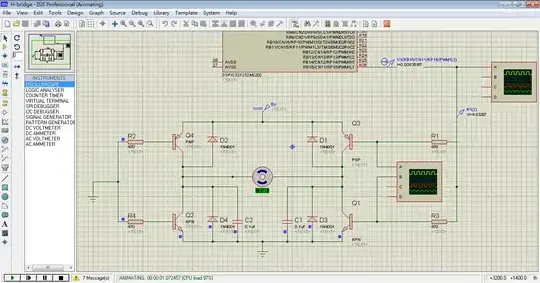

I just saw this picture about PCB 3D printing on a website, can it work in real life? It's would be so cool, if it could useful in the real life.

-

2Which website did you see this? – Andy aka Jan 26 '16 at 10:25

-

6Has this been done? Yes. Does it have a yield above 50%? Yes. Above 90%? No. Is it accurate to 5mil? No. Will it compete with existing technology soon? Probably not. Will it eventually beat existing technology? Possibly, yes. – Asmyldof Jan 26 '16 at 10:28

-

@Andyaka Voltera. – Dave Jan 26 '16 at 10:57

-

23D printing substrates may impose some constraints on soldering processes and temperature profiles... – Jan 26 '16 at 11:14

-

Wondering if it might beat out DIY etching, but I have no ideas about solderability and whether it can hold up to a reflow profile. – Scott Seidman Jan 26 '16 at 13:43

-

@Andyaka element14 3D printing blog: [First Ever 3D Printer for PCB Prepares for Market](https://www.element14.com/community/groups/3d-printing/blog/2015/11/30/first-ever-3d-printer-for-pcb-prepares-for-market) – CL. Jan 26 '16 at 13:54

-

1There's a company that gave a talk where I work a week or so ago that can print semiconductors (10um working transistors from an inkjet printer!). So 3D printing a PCB doesn't sound farfetched after that! – Tom Carpenter Jan 26 '16 at 14:06

-

For applications where part quality, performance and production cost is not very important compared to shortening (calendar) time it might have some niche applications. Widespread use? Not likely in the forseeable future. Modern PCBs are very, very good and have quite inexpensive tooling. – Spehro Pefhany Jan 26 '16 at 19:14

-

looks kinda sloppy to me – squarewav Jan 26 '16 at 23:14

-

mmm ,maybe the cost is a problem – user13077 Jan 28 '16 at 07:12

2 Answers

It can work. I have recently seen an entire speaker built using a multimaterial 3D printer. In the future, it will certainly be possible to print 3D circuits and electromagnetic components (motors etc.) inside products without planning for any openings. A real breakthrough for applications which pay a lot of money for seals, for example. It may also replace the flex-rigid circuits which allow you to have PCBs with bends (to wrap a camera with PCBs for example).

However, nowadays parts made of multiple materials require either a 3D printer which automatically switches between materials (we are talking hundreds of thousands of dollars), or which stops and allows the material to be changed before proceeding with the rest of the part. Note that you cannot even use any material: although plastics and resins are dead-easy, and metals require different techniques (e.g. powder fusing using a laser) generally but can be done very reliably if you throw the money on the table, I am not aware of any proven method (other than very early prototypes) to print fiberglass or polyimide therefore your PCBs will have to be thicker than existing PCBs, will not handle temperature as well or will have a lower breakdown voltage (and therefore a higher creepage distance at high voltage) for example. On top of that, there is the plating to improve the mating of connectors and the soldering. You may not realise this, but existing laminates are very advanced, and use materials which are not ready for printing yet. It is not necessary in all industries and certainly not for domestic use, though.

Property of materials are one thing, and precision is another. The current process to build PCBs is EXTREMELY accurate. Even the cheap PCB houses out there can do tens of 12-18um layers, perfectly round vias of 0.1mm in diameter, tracks as thin as 0.1mm and spaced y 0.1mm, with shapes so accurate you will never see any difference with your CAD view zoomed 10 times and a microscope of the same magnification (I've never had any acid traps issues). It may sound like overkill, but it isn't. You may not need tens of layers, but 0.1mm spacing is very common in dense circuits including surface mounted components and you don't want your 45° mitres to short with adjacent lines.

Finally, I expect the build time to be higher. Photolithography, acid etching etc. form a relatively quick process and the assembly lines are laid out such that the throughput is very high: dip tens of PCBs in a bucket, move it over to another one, while another panel takes its place. Time is money when it comes to production. I would not buy a cutting edge 3D printer that builds 25 PCBs in 3 hours when I can build hundreds in the same time using widespread machinery and chemicals.

When that technology is ready, it will be very good news to many applications (though I suspect, not all of them). In the meantime, it is just not worth it.

- 9,477

- 6

- 51

- 82

-

73D printing excels in small production runs. It's not how long it takes to make 25 more PCB's. It's the time from the design to the first prototype. Latency over throughput, basically. If PCB 3D printing takes off, presumably it will be with dedicated printer designs. The metal traces probably will be plotted, so a 45° angle is no big deal.Still, quite a bit of work to be done. – MSalters Jan 26 '16 at 15:58

-

I strongly advise everyone to use word *probably* whenever making *in the future* assertions. – Tomáš Zato Jan 26 '16 at 16:29

-

3@TomášZato Thanks. For some reason, "certainly" carries a bit of doubt, so I used it instead. – Mister Mystère Jan 26 '16 at 16:32

-

1

-

@MSalters: Thanks, well said. 3D printing is great whenever the tooling to make the product doesn't exist yet. When it does, the cheapest option considering the production run, wins. – Mister Mystère Jan 26 '16 at 16:40

-

thanks ,you gave me a detail and useful answer .Let me understand more comprehensive .you are right ,there are a lot of problems about 3D printing of PCBs ,like The material, conductivity and layers and so on. I think the cost will be very expensive .but this is a great invention , I like to hear that it can work in real life In the near future – user13077 Jan 28 '16 at 07:03

-

@MisterMystère You do no need hundreds of thousands of dollars for a printer that can switch between materials. Multi-nozzle printers exist in the consumer 3d printing space for as low as ~$400. – James T Apr 11 '16 at 08:37

As I understand it there are two main problems with 3D printed PCBs, both related to the printable conductive material.

- The material is expensive (generally silver based). This is tolerable for basic designs but high speed work requires ground and power planes which start eating up the material real fast.

- The conductivity is far worse than copper. That means far greater losses in the PCB.

- 21,158

- 1

- 38

- 76

-

is there a possible that 3D printing technology is widely used in the life ,and it will reduce a lot of machines and Labor costs after solve the problems you raised – user13077 Jan 28 '16 at 07:14