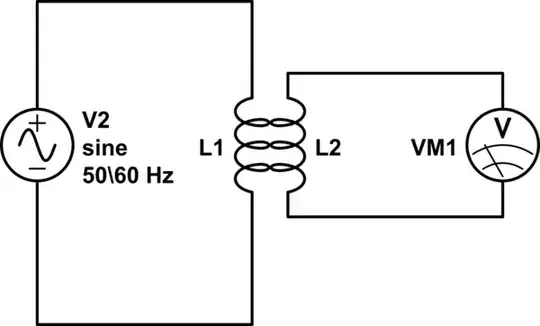

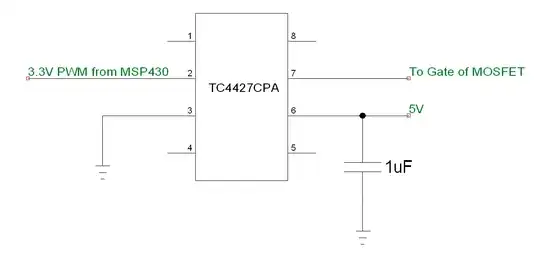

I have constructed a SEPIC converter which is to be used for maximum power point tracking (MPPT). For simplicity, I am currently just using the hill climbing algorithm with fixed duty cycle steps of 0.01. The MPPT algorithm is implemented in the MSP430F5529 micro-controller and the PWM signal from the MSP430 is fed to a simple driver circuit for the MOSFET. The PWM signal has an ON voltage of 3.3 Volts which is what the MSP430 naturally outputs.

The following is the schematic of the SEPIC and driver circuit.

The input is a solar panel with:

V_oc = 6V V_mp = 5V I_sc = 0.67A I_mp = 0.6A

Thus, the nominal output power should be around 3 Watts. The output is simply a 22 ohm resistor.

The FQP30N06L power MOSFET is currently being used on the switch and it is being switched at 50kHz. Now comes the main issue and the reason I am posting this question - During operation at duty cycles at around 0.35-0.5, the MOSFET gets unusually hot - At least 70 degrees celcius in a room temperature environment. On the other hand, I did measure the waveform of both the gate voltage V_GS and the switch voltage V_DS as shown in the figures below.

I did notice that the beginning of the pulses of the switch voltage V_DS has some unusually high peaks but I am not sure what these are. Perhaps someone could also point out why these peaks occur.

So what could possibly cause the MOSFET to become so hot and hence cause my converter to be very inefficient?