Thank you for an excuse to add more photos.

The long term effects of exposure to moisture is often what kills electronics despite the product working perfectly after said exposure.

Different liquids have different effects; some destructive such as corrosion and others constructive such as the formation of conductive deposits.

Water is synonymous with rust; leave water on exposed metal and it will rust whether you like it or not. But only if the metal contains iron (or another oxidisable element, but that's not 'rust') which, of course, all IC pins and other contacts do. This corrosion, if left long enough, could cause intermittent or permanently-broken connections.

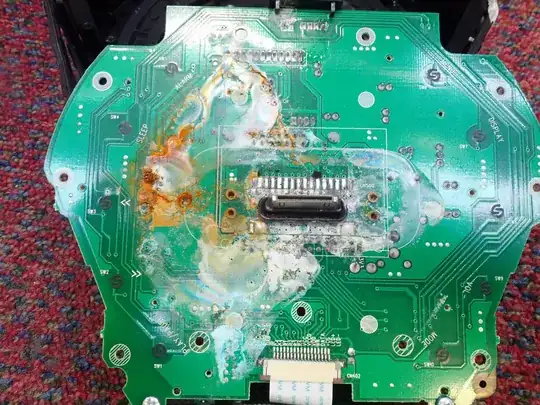

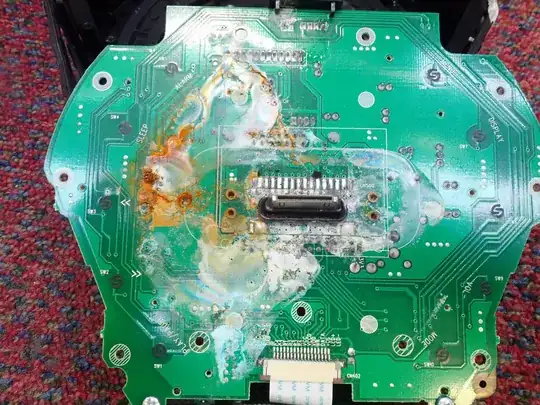

Milk:

Tea/coffee spillage was a common sight at my previous job, along with the testament of "I haven't spilt anything on it, I barely use it!"

Liars, all of them. The white deposit is from the milk. It smells of off milk, which is foul, but more importantly it becomes a conductive addition. I'm not a chemist so I don't know the reason, but milk-based drinks are a real electronics killer, perhaps more so than other spills. These deposits a very stubborn and require a concerted effort to remove them. Surface mount IC packages suffer the most because it's impossible to get behind the pins to clean.

The orange deposits is the residue of instant coffee. Again, it's the smell that identifies it, rather than anything else. Tea leaves a different colour, typically brown. Neither are quite so conductive when dry, but I have noticed imperfections in soldered surfaces after cleaning. Perhaps some mild acidity is wreaking havoc.

Tea and coffee seem to destroy vias. From experience, you can clean all the deposits off and make it look like new but the vias will be rendered useless. This could be due to short circuits being created thus drawing too much current through the via, and so destroying it, but it has always seemed that vias outside of the 'residue zone' remain unaffected. It could be because of the acidic properties of tea and coffee - we've all heard or seen what it does to our teeth.

Coca-cola / fizzy drinks:

When this stuff dries it leaves a horrid, sticky gunk. It doesn't do much in the way of corrosion, perhaps due to a high sugar content, which means that repairs are usually successful. The main characteristic of the gunk is that it never really dries. It stays slightly wet, therefore slightly conductive. In the above example there was a measurable resistance between the pins of SW2 and the adjacent switch, SW3. Needless to say there should have been zero conductivity between the two.

When this stuff dries it leaves a horrid, sticky gunk. It doesn't do much in the way of corrosion, perhaps due to a high sugar content, which means that repairs are usually successful. The main characteristic of the gunk is that it never really dries. It stays slightly wet, therefore slightly conductive. In the above example there was a measurable resistance between the pins of SW2 and the adjacent switch, SW3. Needless to say there should have been zero conductivity between the two.

Mechanical failure is a problem with such spillages: SW3 no longer functioned properly due to the gunk. It would typically stick in the 'down' position. A tactile switch, not pictured, was jammed open due to cola infiltration.

That spillage caused irreversible damage to the plastic lens for the screen, again not pictured.