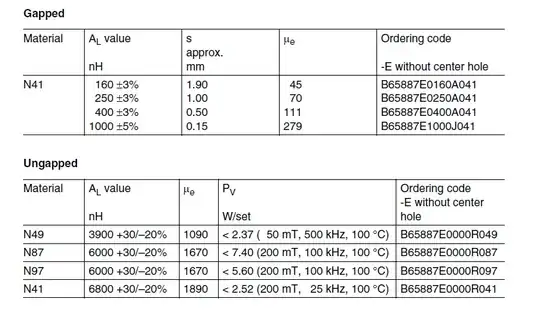

I'm in the process of designing an inductor for a boost converter, and I'm having a hard time finding exactly what I need for this project. I have found a core size/shape that appears to work except I can only get the core in the material I want (N49) in an ungapped core (s = 0 in the image below). Running the calculations for this core, it looks like with the \$A_L\$ value listed, I will saturate the core before reaching my target design current. However, the core is large enough that if I could decrease the \$A_L\$ I would have a viable design. So I think I want to add a gap to the pre-existing core.

How can I add a gap to the core without compromising performance? I've come up with a few methods listed below, but I'm unsure what is "best".

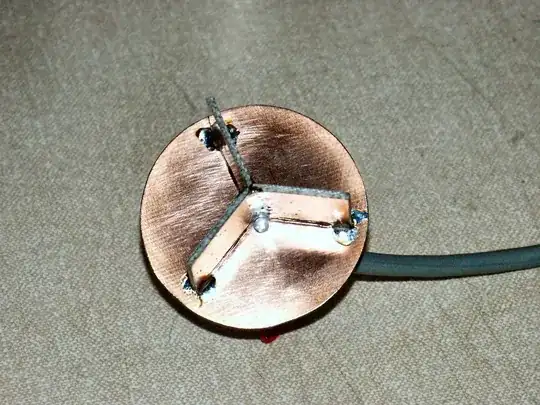

- Place a thin film (e.g. Kapton tape) as a gap material on both the inner post and outer legs. Easy, but the coil is supposed to be centered on the gap (right?) and it won't be centered on the outside legs.

- Sand down one of the center posts carefully. I'm concerned about being able to estimate the required turn count as the gap size determines the effective \$A_L\$. Also, I am unsure how critical it is that the two center posts are planar when there is a gap.

- I'm doing something "weird" and there's a good reason why I can't find what I'm looking for.

For the background, I'm trying to make an energy storage inductor for a boost converter operating at higher frequencies (500 kHz), higher current (>12A), and higher inductance (>200µH).