I'm partially rewinding a toroidal transformer just for the pure thrill of controlling the output voltage. I'm sure I'll get over it, but for the moment that prospect is pretty exciting for some reason :)

I'm leaving the 120V primary in place (I removed a second 220V "extension" primary winding) which is good because it's about 1500 turns. I'll wind a new secondary or two and then wrap it back up.

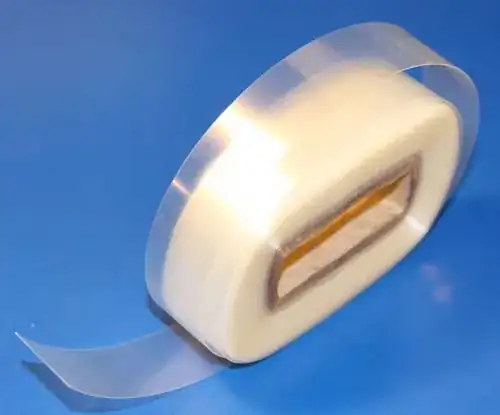

On the outside and between the primary and secondary windings, the transformer is wound with a clear plastic tape (no adhesive backing) that is 12mm wide and 3 mils (0.003") thick. I'm sure it performs a mechanical protection role and given its inter-winding appearance an electrical insulation role as well.

I notice the tape is pretty stiff (not floppy or stretchy to speak of) and holds the kinks from its original winding position pretty clearly. It occurred to me that it might be some sort of heat-shrinkable tape that stiffens and holds bends once it's been shrunk. That would make some sense I suppose because the shrinking would insure the winding underneath was tightly bound and less likely to become noisy or whatever.

Does anyone know what this stuff is and whether it's available in modest quantities for prototyping purposes etc.? Or perhaps whether it's okay to reuse it?