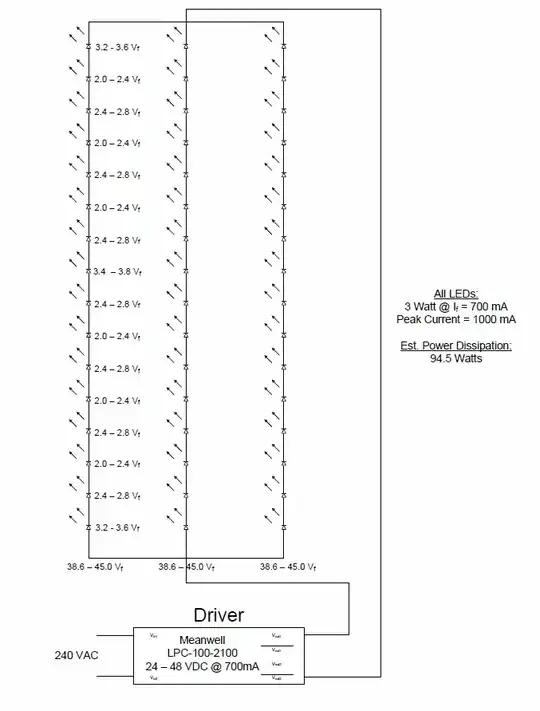

I'm designing an LED array for use in a grow operation. I've selected the 3 Watt (700mA, 1000mA peak) LED's and a constant current driver (Meanwell LPC-100-2100) and laid them out in a series/parallel configuration (see diagram).  Three (3) series strings of 16 LED's connected in parallel to the LPC-100-2100 driver. My question is this, if one of the series circuits fails, will that cause the 2100mA to be split between the remaining 2 series legs (1050mA each) and subsequently overpower and destroy the remaining LED's? If so, is there a limiting circuit that I can build/buy to protect for this situation? Or will a simple .75A or 1A fuse suffice?

Three (3) series strings of 16 LED's connected in parallel to the LPC-100-2100 driver. My question is this, if one of the series circuits fails, will that cause the 2100mA to be split between the remaining 2 series legs (1050mA each) and subsequently overpower and destroy the remaining LED's? If so, is there a limiting circuit that I can build/buy to protect for this situation? Or will a simple .75A or 1A fuse suffice?

- 1

- 2

-

You may wish to proof read and correct the typos in the question title and the first paragraph '700mA, 100mA peak'. – Transistor Dec 07 '15 at 00:24

2 Answers

You don't need one limb to fail for this to happen. If the string on the left had mainly LEDs with lower forward voltages (compared to the other strings) it could hog maybe half to two thirds of the current.

I wouldn't advise this type of configuration on that basis alone. Either put them all in series or use individual drivers.

- 434,556

- 28

- 351

- 777

-

Andy aka I've arranged all 3 legs to have equal total Vf's (38.6-45.0 V) on each. Is that a better situation. – MarvH Dec 06 '15 at 19:20

-

2No. The only sensible, survivable solution is 700 mA per each string. LED voltages are neither well specified nor stable over temperature. Current is what needs to be controlled, and you will not get anything like adequate current control from a "divide by 3" approach unless you are burning a crap-ton of power in resistors (and that won't protect from a string failure), or you are dividing ahead of (however many you like) 700 mA drivers (when driving 700 mA LEDs) – Ecnerwal Dec 06 '15 at 19:27

-

It is very wise to have current control per leg.

However, if LEDs are reasonably well matched and when a large number are used in series per leg then Vf total per leg will often be close enough to be OK.

Adding a series resistor per leg to drop say 5% to 10% of the total voltage allows for balancing if legs are reasonably well matched.

A simple protection scheme is to provide a series current limiter per leg which is normally not in current limiting mode but which limits an individual if current rises. An LM317 constant current source will do this - will need to use HV part at 48V and check specs. Run at say 800 MA CC so usually "wide open".

Many LM317 CC circuits here

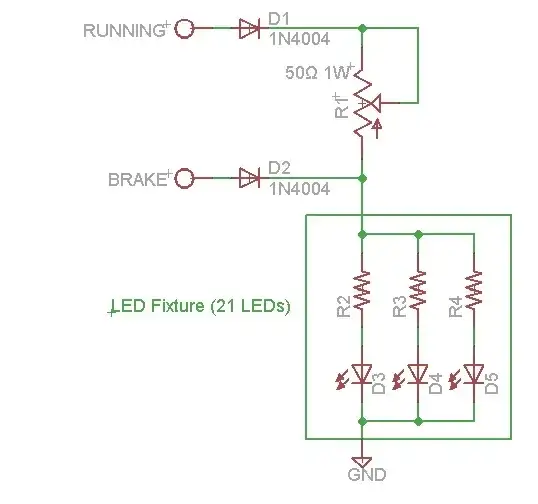

eg From here

LM317 datasheet here.

Digikey pricing for TO220 1A+ part here.

Fig 10 in datasheet sjhows dropout voltage at various currents and temperatures. At 700 mA and 25C it is advisable to allow 2V drop across the LM317 plus an additional 1.25V drop across the current sense resistor or about 3.25V total. At Vf = 38.6V this dissipates (3.25)/(3.25+38.g) x 100 % ~= 8% of the voltage if just enough voltage is fed by the supply. With slight supply "headroom" and allowing a little more voltage for string voltage mismatches say 5V is dropped by the regulator + supply (maybe more) so LEDs are about 88% efficient.

At 700 mA and 3.25V in regulator and 1.25V in resistor Power_regulator = VI = 3.25*0.7 = 2.3 Watt and Power_Rsense = VI = 1.25*0.7 = 0.875 ~= 1 Watt.

Datasheet says TO220 Rth_ja = bare pkg in air = 70 C/W unheatsunk so Trise at 2.3W = too much. Rth_jc = junction case = 5 C/w so a modest heatsink will hive an acceptable rise. (eg 20 C/W heatsink + case at 2.3 W - temperature rise = (5 + 20) x 2.3 ~= 60 C rise above ambient.

LEDs will each be powered at 1.5W to 2.5W DC input with perhaps 25% of that leaving as light - so LED heatsinking is going to be a far more significant challenge than regulator heatsinking.

At about 33 Watts per string if Ta = 35C (design conservatively) and T_LEDs operating = 85C then Rth LED + heatsink is allowed to be dTemp/W = (85-35)/33 ~= 1.5 C/W heatsink per leg. Fan cooling or lot of metal are liable to be needed.

This stack exchange question also discusses this issue.

- 147,325

- 18

- 210

- 386

-

If you are going to build a current source per leg **anyway**, just build it at 700 mA and skip the "series resistor per leg to drop say 5% to 10% of the total voltage" - You also don't need the HV part unless you are connecting it to so few diodes that there will be more than 40 volts across the LM317 from in to out. Direct quote: "Because the regulator is *floating* and detects only the input-to-output differential voltage, supplies of several hundred volts can be regulated as long as the maximum input-to-output differential is not exceeded. That is, avoid short-circuiting the output." – Ecnerwal Dec 07 '15 at 00:33

-

So if I'm reading this correctly, all I need to do is size R1 at 700mA or R1 = 1.25V/.7A = 1.8 Ohms (Power = 1.25*1.25/1.8 = .868 Watts) with a 1 Watt power rating and apply one of these to each series leg, correct? – MarvH Dec 07 '15 at 14:02

-

@MarvH More or less. If the psu is adjustable as the text suggests is the case then it MAY be advantageous to set the current limits are at say 800 mA but adjust the overall voltage so that the legs each draw ~= 800 mA. That way the dissipation in the regulators will be minimised until they are needed due to a fault. Regulators need to be heatsunk to carry worst case dissipation = Ireg x (Vin_max - Vstring). LM317 drops ABOUT 1.5V dropout at 700 mA so at 700 mA that's about 1 Watt dissipation. R1 will also dissipate 1.25^2/R1. – Russell McMahon Dec 08 '15 at 04:10

-

-

I understand the suggestion to limit the current to 800 mA to minimize the heart dissipation from the regulator but doesn't that allow 800mA to flow through the LED's which are maxed out at 700mA and pendant damage them? – MarvH Dec 09 '15 at 16:52

-

@MarvH Using always-active current limiters is a reasonably good idea if you don't mind the slight decrease in efficiency. An LM317 drops about 1.5V If you use resistors and an adjustable power supply so that Iusual is 700 mA per string (or if strings are well enough balanced just adjust supply Vpout so Imax in any string is 700 mA then the limiters will only function when a string goes OC. .... – Russell McMahon Dec 10 '15 at 11:57

-

.... Modern LEDs may be modestly overloaded for substantial periods with only moderate reductions in lifetime. eg if heatsinking is good then occasionally running 700 mA LEDs at say 800 mA for say 12 hours per month (ie an overnight string failure per month) may take 5% to 10% (if that) off their overall lifetimes. Degradation rate increases non-linearly with increasing overload. – Russell McMahon Dec 10 '15 at 11:57