I'm looking to capture and analyse measurements of the mains energy that I use per circuit.

I've found a few consumer products that offer powerpoint energy monitoring such as the Kill-A-Watt, but PC connectivity needs to be hacked into devices like these, and while more advanced units offer builtin USB, I'm not aware of anything off-the-shelf that comes with drivers/support for FreeBSD.

My attempts to find DIY energy monitors via Google have failed dismally, as I'm not entirely certain what to search for, but I did find one particularly interesting-looking PDF on power monitoring, which describes a variety of different software-based power monitoring techniques and how to implement them.

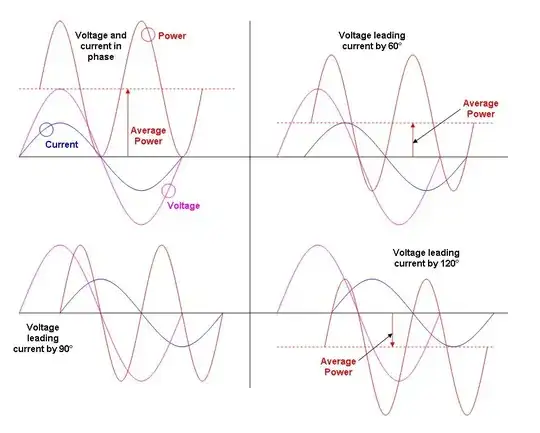

One of the things this PDF highlights is the relationship between voltage, current and power factor, and the fact that you cannot accurately calculate energy usage (wattage) without voltage and current, and that the power factor must be taken into account as well. I'm generally looking for a measurement solution that tracks voltage, current and PF.

The Kill-A-Watt would appear to be the most effective, simplest starting point to measuring voltage and current (and thus PF), but I'm concerned about using this device for a couple of reasons:

- There are several variants of the Kill-A-Watt circuit design out there, apparently from different contracted OEMs. Hacking instructions only seem to be available for one variant.

- The PCBs do not use a full voltage converter or transformer, so all components operate at 240V potential. I would describe my electronics experience as "extremely rudimentary," so I regard modifying a device like this as firmly out of the scope of what would be a good idea for me to tackle.

- The listed designs are for the US version of the Kill-A-Watt, but I am in Australia. The Australian design is completely different (entirely different enclosure, etc) and completely undocumented. I understand the Kill-A-Watt will probably handle 240V as the US uses a split 120/240 system, but still.

- Reading this forum discussion thread, I get the impression that not only is the Kill-A-Watt device design itself not especially advanced, but that the voltage/current monitoring hack itself could be pulled off standalone without the Kill-A-Watt in the first place.

With these considerations in mind, I'm looking for an inexpensive way to track the power consumption of my computers and other peripherals in realtime.

I have a corner I can shove a good square ft. of equipment into, so the solution does not need to be compact. My only requirements are that the system track current, voltage and power factor, and be moderately easy to build (I would describe my soldering skills as acceptable).

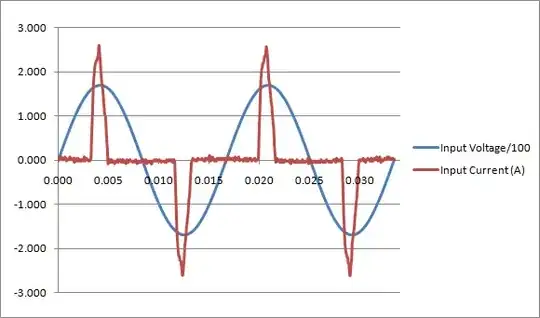

Software design is not at all a problem, and a microcontroller-based design would be fine. In fact, one of the things I do like about the KAW hack is that (as noted by one of the posts in the thread I linked earler) the system captures circuit current and voltage 17 readings times a second (for PF calculation). This is pretty cool, and would make for nice graphs :)