Background

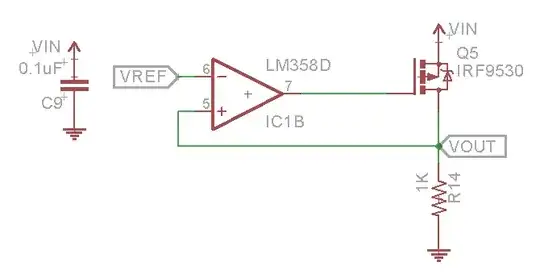

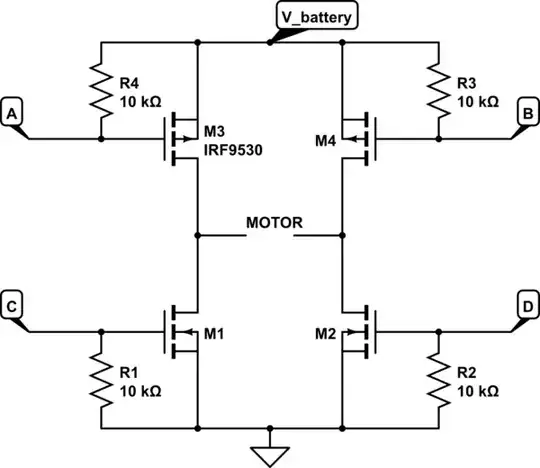

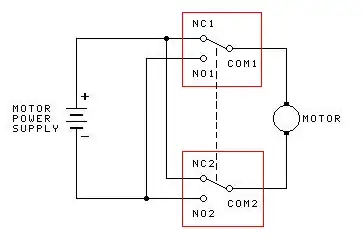

I made 4 of the following push pull circuits like the one below, to use as two H-bridge drivers for motors (stall current about 5A.) Sorry for not drawing the Darlingtons in full, I did this in Microsoft Paint. The Darlingtons have an integral reverse diode.

My criteria were:

-Forward, reverse and stop available (no particular interest in using the motor as a brake)

-Buildable on stripboard

-No possibility of both power transistors being switched on together due to incorrect input signals

-Component count as low as possible.

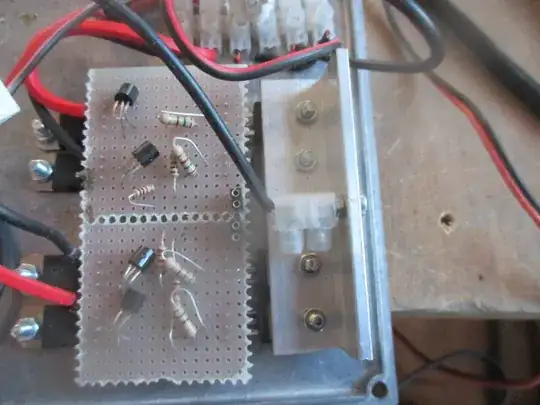

I solved this by using back-to-back emitter followers in a push-pull arrangement. I was able to bolt the collectors of Q3a-d to the chassis, and Q2a-d to a bracket/heatsink connected to the positive supply, in order to keep the supply current off the stripboard. The connections to the motor were made with wire all along the stripboard trace to avoid excessive current on the track, See below. +12V Supply wire is black because it is from an inline fuse which has black wire.

See below (please ignore the way the components have been crushed and the way I made the connection to the positive terminal).

Question

The base - emitter voltage for a Darlington is about 1.2 V, so everything works well. The only thing is, the current gain of the Darlingtons is about 750, which means the value of R2 is quite low in order for Q2 to switch on properly. This in turn means that R2 draws quite a lot of current when Q1 is switched on.

It seems MOSFETS are the way to do things like this these days, but there is a problem. For example in the datasheets for the IRF3205PbF and IRF5305PbF it seems in page 3, first image, a 4.5 V gate-source voltage will give about the right current. But there is no data for lower gate-source voltages.

Is there a way to replicate / improve on this circuit with push-pull MOSFETs in common drain / source follower mode? All the MOSFETs I have seen require too much gate-source voltage to switch on to be able to be used in push-pull mode with the drains connected to the supply rails.