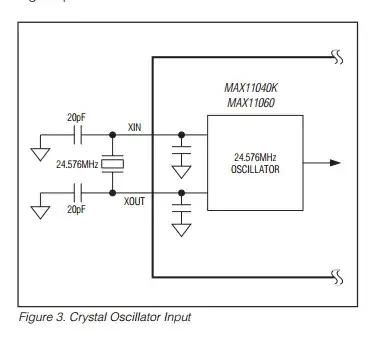

I am using a MAX11060 ADC in a project, I have established SPI communications and am able to read and write registers, however I am unable to get any readings, I believe this is due to the crystal not operating correctly.

This assumption is based on before enabling the oscillator 0V when probed, after enabling the oscillator I see a flat 800mV or so.

To backtrack a bit to fix a screw-up in our board design (wrong footprint) we have manually broken out the package and encased in epoxy (as in I REALLY don't want to re-solder this).

I presume the extra capacitance and/or larger loop area has pushed the crystal out of its operating zone.

Is there any way to measure the load capacitance and then adjust, is this as simple as using a multi-meter to measure between each side of the crystal and ground ad adjust to match the rated value.

Can this be done with the crystal in place.

(Also yes I understand mounted like this the chip will not be able to reach its 16 bit performance, the project has reached a it would be good if it would work at all state)