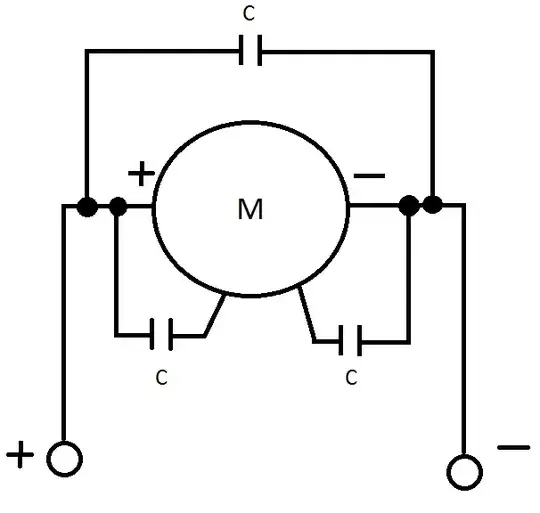

So I've found a motor circuit which looks like this:

Since many users here believe that my hand-drawn circuit schematics are in fact pictures of flying spaghetti monster, I'll also provide a written description:

There are two input lines marked + and - going to the motor. There is a capacitor connected in parallel with the motor. There is one capacitor connected to the positive side of the motor and the motor's metallic body and there is one capacitor connected to the negative side of the motor and the motor's metallic body. The capacitors look like multilayer ceramic capacitors and have capacitance of \$0.1 \mbox{ } \mu F\$. The motor is a Kysan Electronics FK-180SH-3240 DC motor. It is also worth noting that the motors have nominal voltage of 3 V, but are powered by a 2 cell LiPo battery and are controlled by a microcontroller-based circuit.

So my question is: Why use 3 capacitors, with two being connected to the motor body? It would seem logical to have capacitors on motor terminals to keep interference away from the microcontroller, but I don't see how having capacitors soldered to the motor body would help.