This is a follow-up to this question I asked years ago.

A short summary:

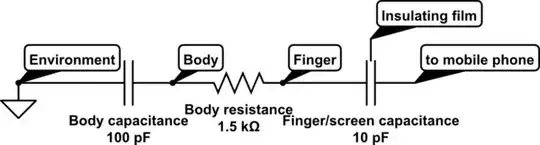

I'm using a head pointer (see my linked question for a photo) with a tip made of plastic, thus non-conductive. The shaft is metal, and conducts well enough for a smartphone touchscreen. My goal was/is to make the tip effectively conductive so I can operate devices with capacitive touchscreens

My experiment

As my initial attempt I chose something as non-invasive as possible (as opposed to crafting a new tip) and decided to draw conductive traces on the existing tip. I chose this CircuitWriter pen to draw several traces connecting the very tip (i.e. the surface that comes in contact with the keys/the touchscreen) and the metal shaft of the head pointer, hoping the resulting path(s) would be conductive enough be registered by touchscreen. Well, disappointingly, it was not the case. As to why that is, I am lost.

Here is a picture of the result:

It shows one path going up to metallic shaft, but there actually three one. The tip of the tip is fully coated with the conductive polymer. Basically, all that is (light)-grey are CircuitWriter traces.

After applying it, I let cure at 15cm from 40W light bulb for 2h+, tested it carefully, re-applied, cured and left overnight.

My attempts at fixing it

When at first it not work (no reaction neither by an iPhone nor by a Sony Xperia), I suspected one path to the metal shaft was not enough and drew two more paths. Still did not help.

Another guess: there wasn't enough contact betwen the plastic tip and the metal shaft. I wrapped the critical region with tinfoil to guarantee a conductive path. Still, did not work.

Do I need to apply yet more of the stuff? Why doesn't it conduct?

UPDATE 27 June 2016 - I solved my issue. Posting my finding for others as information.

I had no luck with the CircuitWriter, so a different approarch was attempted, which does work. The reliability of it (in regard of beeing registered by a touchscreen) depends highly on the "craftsmanship", but not so complicated that it could not be done by average people with average tools&materials.

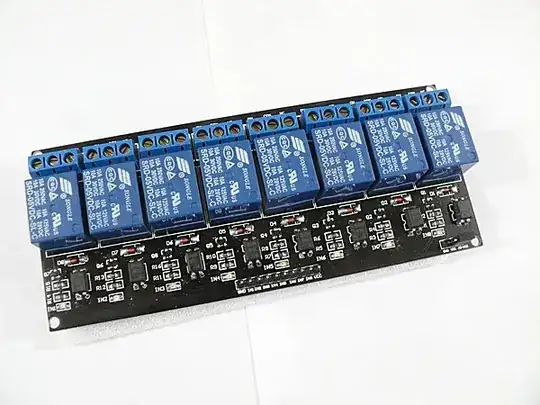

So, a piece of conductive foam was used, the kind that comes with graphic cards and such nowadays. The foam was rolled tighly (or in my case I wrapped it around a Q-tip with the help of a thread to add stability) and connected with simple copper wire (for capacitance) and the whole thing was placed into the stick, thanks to it beeing hollow. That looks a bit ugly and primitive, but is working. Here are the photos

Still I am not completely satisfied. This construction is not very robust and the first incarnation failed after about 2 weeks due to the foam wearing out from typing. The positive aspect is that it is soft, so there is no chance of you scratching the screen.

The next approach I will try will be some adhesive copper tape, as suggested by HighInBC and Dmitriy Grigoryev. Should I post the results then?