I am making a obstacle avoiding robot and wanted to power it with mobile phone batteries. But wondering how to solder wires on battery correctly for no inconvenience.

p.s. I am a new arduino enthusiast.

I am making a obstacle avoiding robot and wanted to power it with mobile phone batteries. But wondering how to solder wires on battery correctly for no inconvenience.

p.s. I am a new arduino enthusiast.

Don't.

The battery manufacturers specifically tell you not to do this, as the batteries are quite heat-sensitive. If you manage to set one on fire, you can't extinguish it either: it reacts explosively with water, so you have to bury it in sand or powder.

The correct solution is to get spring-loaded contacts or "pogo pins", attach them to a PCB or piece of Veroboard, then attach the wiring to that. You can then either build a battery holder nicely or use tape or elastic bands to hold it in place.

(The manufacturers use electric or ultrasonic spot welding to attach wires to battery terminals internally.)

Step one is trying to avoid wanting to solder to any kind of pre-fab battery, as you don't know 100% for sure what's in them in ways of protection.

Step two is really thinking hard if you can't stick to step one.

Step three would be: Very, very carefully.

To expand on step three:

Many single-purpose pre-fab lithium cells for such things as phones will have very limited protection, if any at all, against short circuit or internal discharge avalanches and what not, and will generally have 99% battery in them, so the chemistry will be close to the contacts.

So over-heating is a serious danger, as that can damage the internal barriers and cause excessive internal leakage, which can quickly cascade into a damaged battery, or one just about ready to explode. For circular, metal-can cells this risk is very low, due to construction, but for flat LiPo cells, with low thermal mass at the pins as well, this is a good possibility.

Apart from that a short circuit on the pins while you are soldering is also a very serious risk. The plastic that holds the contacts will be extremely low grade, so if you heat the pins for more than a second or two, they may come loose and presto-sparking.

Short circuiting a LiPo cell with no internal protection may also cause outgassing or explosion if you are unlucky, both potentially seriously shortening your life expectancy.

The one advantage to this is that most cell phone batteries come with gold plated contacts and solder should fairly easily stick to them.

But if you MUST: First practice soldering small contacts a couple of times to get competent at it and only then try soldering onto the cell, making sure you never heat the contacts for long stretches.

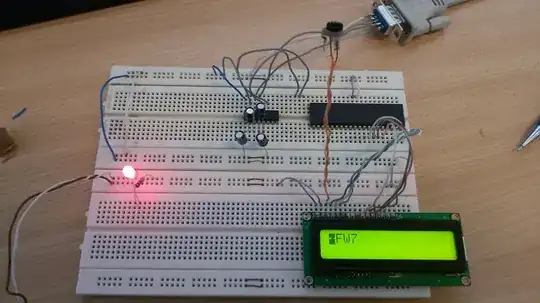

There are Li-ion batteries and battery packs designed specifically to be soldered, which usually look like this:

I'd strongly suggest you buy one of these instead of trying to reuse a cell phone battery. Your device will most probably be badly soldered and thus unreliable if you do. There's aslo a danger of shorting or overheating the battery while holding it right in front of your face. Lithium is not that good for the eyes they say :)

If you already have the batteries, pogo pins are the way to go.

Use conductive glue. Here's an example. A few caveats, taken from the reviews:

It isn't tacky.. so either use a clamp, or be prepared to hold the object (for a long time.) It's thin & watery..apply sparingly in layers. ...and even after it's dried to the touch, it won't conduct electricity very well until it's sat for at least a few days to thoroughly dry.

It gets brittle.. and will crack away under any kind of stress or tugging.. so be prepared to reinforce whatever you're mending with either tape or an additional application of epoxy.

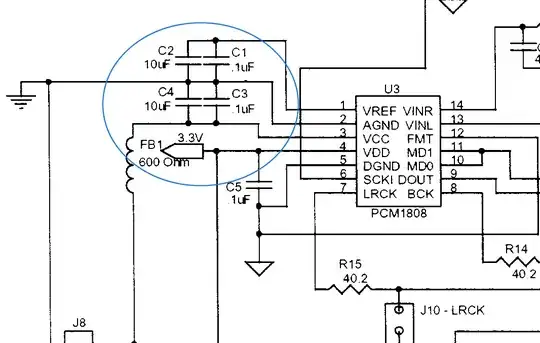

If the battery is replaceable and has gold-tinned pads like this:

Then they have protection circuit and the pads are on a small PCB. You can solder to these pads like you would to any PCB (don't use more heat than needed, but it is not particularly sensitive).

However, if it has wires or connector directly coming from the battery, like this:

Then the battery most likely does not have protection circuit so you probably should avoid using it at all. If you do, you can carefully solder to the wires but never on the battery itself.

Been doing this off and on for years.