I've recently acquired some LM2596T-5.0 3A buck converters. They are TO-220-5L packages with bent leads similar to this image:

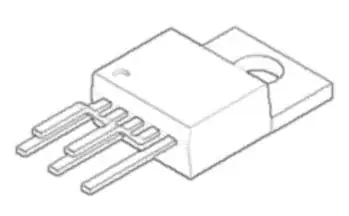

I have seen other TO-220-5L components with straight leads like this:

My question is whether there is a good reason why they are bent (arcing, magnetic interference, etc) or is it just to make mounting easier, or some other reason. The bent lead don't work very well on breadboards or prototype boards so I have straightened them and then fanned them out a bit so they will fit but I just wondered if this would cause me a problem at some point.