What is preferred way to panelise a Metal Core PCB (MCPCB) - V-scoring or Tab-routing?

The engineering challenge I am facing is that the boards are meant for production (1,000 qty in the initial stage) and unfortunately the most economical SMT Assembly house that I am in touch with cannot depanelise the boards for us.

So the option is either to move onto a more equipped assembler (they are twice as expensive(!)) or depanelise the PCBs on my own.

Some notes on the board design:

- It only has LEDs. No resistors or capacitors.

- The LEDs are 2.3 mm away from the board edge.

- Overall PCB thickness is 1.6 mm.

- Boards are rectangular, mostly.

- PCB is 25.5 mm x 21.25 mm.

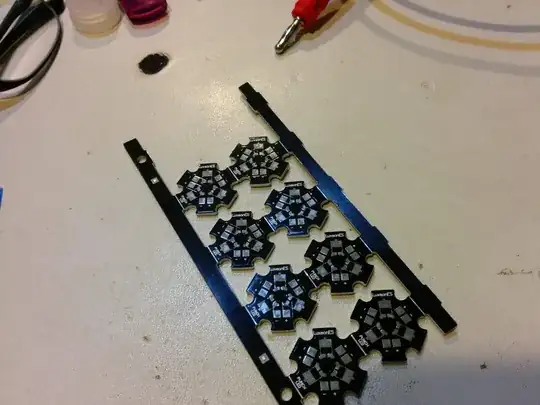

- Panel is 5 x 8.

Considering the above, is it a better option to V-Score or Tab-route? What method will allow me to minimize board stresses?

And furthermore, what is the recommend way to depanelise a MCPCB (goal being cost-effectiveness & minimized stress on the components?)

Note: I understand that at a higher volume, I will need a better and more automated way to handle this. However, for now, I am mostly concerned about the 1,000 quantity. I am also open to the idea of redesigning the board.

An idea that I had after typing this question: I should design the panel to be tab-routed. After assembly, I could use a manual milling machine to break apart the PCBs. Will a milling machine cause stress on the components/PCB?

I have access to several milling machines and cheap labour. This is not a big issue.