They have a 5x5cm minimum board size. My board is approx. 35x20mm so I can easily put two side-by-side and thus double the board count within this limit. What is the best way to do this? I know how to duplicate it in Eagle, but would I set them apart, say 2mm, and design a connecting bridge with drill holes to make breaking apart easier?

-

Personally, I'd go with a different board maker. I like pcb-pool.com – Scott Seidman Jul 06 '15 at 21:06

-

See http://electronics.stackexchange.com/q/137292/11684 re panelization – Scott Seidman Jul 06 '15 at 21:07

-

Great info, thanks everyone. I would also like to ask what your views are on pads all the way to the edge of boards. I have a few specific parts that need to be placed directly on the edge. Osh park CNCs the boards nicely and the pads aren't effected. Will other prototyping services show similar result even though it doesn't meet design rules? – Fid Jul 07 '15 at 04:56

3 Answers

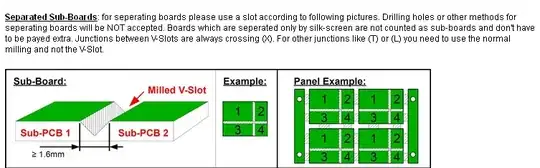

Assuming you are referring to the prototype service by the name in your title, you must use V-grooves rather than drilled holes.

They will almost double the price on you anyway (8.55 EUR), so I doubt it's worthwhile.

Always read the conditions and rules carefully, there are often such gotchas in the details.

If you have a metal shear you can just space them apart, add silk screen markings and shear them when they arrive. The FR4 does tend to dull the shear.

- 376,485

- 21

- 320

- 842

As Spehro noted most cheap board houses will charge some extra fee for panelizing multiple boards. In their case it may just be the extra step for the v-score, in other's it could be part of their business model.

What I usually do in this case is panelize my design, using something like CAM350, although you can use whatever you like. I clear out 1/4" or more between any copper feature for each instantiation of the board. Then I just submit it like that, when it comes back I just cut them out on my band saw.

That's not the kind of thing I do for production, or at work, but at home when I'm being cheap it works.

---Edited for safety---

Adam makes the good point that you should use breathing protection when doing this as shown in this question which also advocates scoring the pcb with a knife and breaking it as a safer alternative.

- 15,815

- 1

- 31

- 44

-

-

1Yes I think you're right, this post describes it in detail including the MDS recommendation, although those masks aren't really very expensive http://electronics.stackexchange.com/questions/93624/what-are-the-dangers-of-cutting-pcb-with-dremel – Some Hardware Guy Jul 06 '15 at 22:08

There's a price comparison site for PCB manufacturing called PCBShopper.com. You enter your board's specs and it shows you prices and delivery times from over two dozen manufacturers, including the best known companies in Asia, North America and Europe.

One of the specs is the number of designs on your board. Some companies will charge extra for multiple designs, even if you're not asking them to cut V-grooves or otherwise separate them (i.e. you plan to cut the boards apart yourself). But the cheap Chinese manufacturers do not.

- 1