Seemingly illogical pinout has been discussed before, but my question is different.

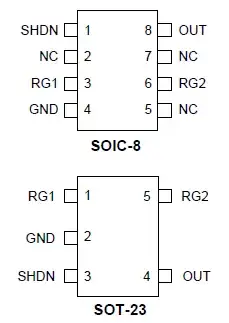

Have a look at the pinouts for the Si8540:

One would think that the pin order would be the same for both packages, maybe rotated, but that would be it. Instead the SOT-23 pinout is almost a mirror image of the SO-8's. Now SO-8 nor SOT-23 are flip-chip, so the die isn't mounted upside down on either, and I can't imagine that they would make a different die for the other package. I can only presume they crossed the bonding wires.

Looks like asking for trouble IMO, so why is this done? I can't think of another explanation.