Simply put: the datasheet is your complete encyclopedia on a part. A good datasheet will tell you everything you need to know about it. Use this information. Most design errors are due to (deliberately or not) overlooking certain specifications in the datasheet.

The most obvious thing the datasheet will give you the part's pinout, so that you know how to connect it. For a 144 pin controller it's obvious you can't do without that, but you may need it for a simple diode as well:

For relatively simple components the datasheet will mostly consist of numbers, either in tables or in graphs. One of the first tables in most datasheets will be Absolute Maximum Ratings. These are often interpreted wrongly. Not only do they mean that operating the part above the given values will damage the part, but you're also not supposed to apply these ratings in continuous operation. Absolute Maximum Ratings should only be met in exceptional situations, and never exceeded.

Next you'll have voltage and current ratings, like power supply range and consumption, and voltages and currents on specific pins. This will often be minimum and maximum values. Importance: calculation of power budget, and ascertain that you can connect part A to part B, in terms of matching voltage and required current.

In particular for digital ICs threshold values are given, voltage levels where a logical zero toggles to a logical one or vice versa.

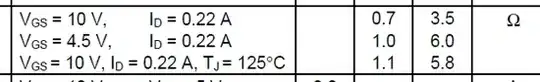

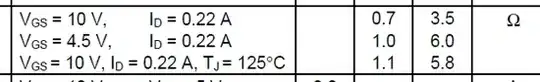

Note that values are often given as minimum/typical or typical/maximum pairs, and under the given conditions. Always work with the extremes! The following gives \$R_{DS(ON)}\$ for a BSS138 MOSFET:

The first line says 0.7\$\Omega\$ typical, 3.5\$\Omega\$ maximum. This should be read as "Most parts will have the lower value, but don't be surprised when you see the higher on certain parts." If you design for the typical value, the ones who are closer to the maximum value may not work properly in your application! In this case you may underestimate dissipated power, so that the FET will overheat and fail long before the product's expected lifetime.

And the manufacturer almost never gives a probability curve telling you how many parts will actually have this higher value. So that means you might as well have 20% not-working products! Again, always work with maximum value.

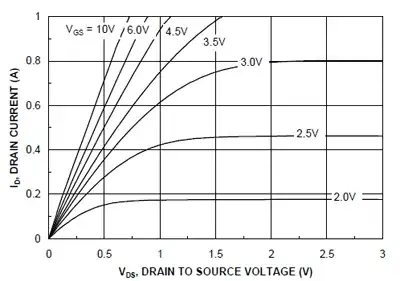

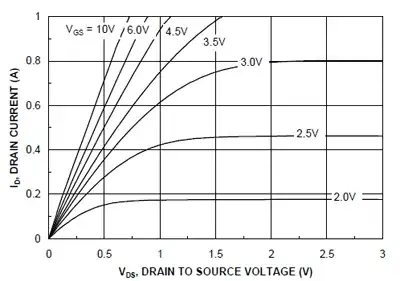

In the spirit of "a picture's worth a thousand words" most datasheets will have a number of graphs, relating two parameters against each other. You'll often see the same types of graphs again and again for certain components, and that helps comparing them. For a (MOS)FET for instance one of the most important graphs is \$I_D\$ vs \$V_{DS}\$,

and once you get acquainted with FETs you'll recognize this specific graph immediately. (Many design engineers will first look at the pictures in a datasheet because that's the fastest way to find specific information in a sometimes long document. That's why we graduated with honors in kindergarten!)

Many datasheets will also have one or more schematics, first of all a typical application. This should get you started when you're using the part for the first time. National's analog datasheets have a great reputation of providing many application examples.

The datasheets for Linear Technology switching regulators, on the other hand, also have much application information, but more in prose, explaining theory of operation and calculations for example.

I'm just naming a few, but you'll learn that every manufacturer has his own datasheet style, and his own focus.

At the end of the datasheet you can find mechanical drawings of the part's package, and sometimes also recommended PCB footprints. The latter is often published in a document on the package, however, because it is common for all devices using that package.

The above lemmas are more or less common for most datasheets. But you can't compare the datasheet for a resistor to one of a microcontroller, of course. Especially the latter needs some getting used to. First of all, they're long! 100 pages and more are no exception. There's nothing you can do about it, they simply can perform so many functions, and everything has to be described in detail. In a microcontroller datasheet you'll see more prose than in other datasheets, because most functions can't be described just in numbers.

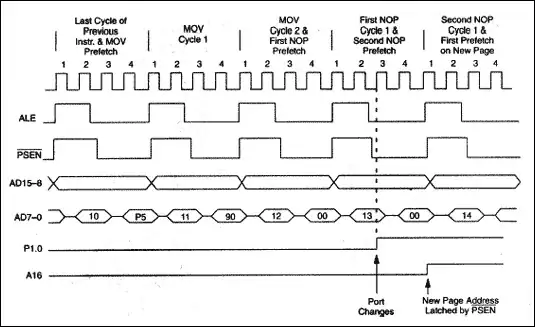

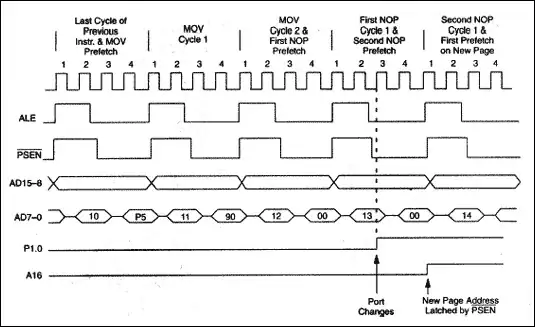

Microcontrollers and other digital IC datasheets also often have timing diagrams, again a picture which can tell a lot which would be difficult to explain in words.

Again, they're eye-catching, so you'll find them easily.

Typical of microcontrollers is that they're part of a family, meaning there are related parts with other on-chip peripherals. To avoid having a great deal of the information identical between devices, and thus having even longer documents, most manufacturers choose to extract the common information from the datasheet and publish it in what's often called a family user manual.

You'll have to check especially the numbers when reading a datasheet. I've seen several designs fail (and I made errors myself) because the designer missed or misinterpreted some value in the datasheet. Use the information.

Before the 'Net and PCs there were databooks with collections of datasheets. Today you can find any datasheet on the manufacturer's website. If you can't find the datasheet, don't use the part!

Especially longer datasheets have an advantage in being available electronically (PDF). You can search the datasheet for certain keywords, and long datasheets like for microcontrollers have a structured table of contents with bookmarks. Again, use them!

There's a lot more to be said about datasheets, watch for more answers, but it's important to (learn how to) read them. They should give you the information you need to create a working and reliable product. If you can't find some specific information, call your distri's FAE!