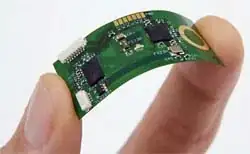

I'm working on a project to make a wristwatch similar to this one:

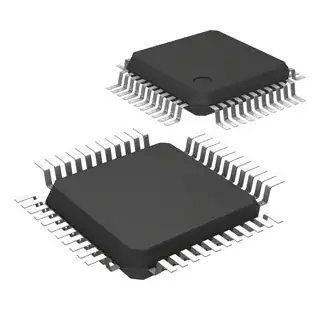

Now I have the ability to make flexible PCBs since I accidentally bought some crazy thin copper clad. I obviously want to use SMD LEDs since they're pretty small. What type of \$\mu \$C package should I look for that will be nice and thin but still DIY solderable (the only one I know of is QFP but I'm not sure I could solder one of those)?

Lastly, are there any other common pitfalls when making flexible circuits? I can imagine people bending the PCB all over and accidentally touching traces etc.

EDIT I'm thinking about not making the circuit flexible, but storing components inside each little compartment of the watchband. Then I just need flex cables to go between the parts of the watchband for communication and power. Probably only need a few traces... this would lessen (almost eliminate) the stress on any solder joints and place it only on the material the communication traces are put on. Whether I decide to make that out of polyimide or just my thin FR4 is yet to be determined. Does this seem reasonable?

Thanks