I have seen quite a bit where reverse biased diodes are used to clamp input voltages when spikes occur.

- What is the typical reverse breakdown voltage for a diode used in this type of application?

It appears that these protection diodes are in place not to protect against a large applied voltage by the user, but rather are in place to snub voltage spikes that may arise from static discharges.

Why might a static discharge occur, where would this excess charge come from in-circuit (on a PCB, not bread-boarding where a person may introduce discharge), and what is the typical voltage magnitude?

Why would one not also consider the possibility of a potentially large negative voltage and also place reverse diodes from the input line to Vcc?

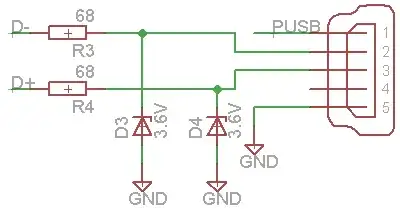

I am designing a simple breakout board for a controller that will output data through a USB interface. Through my research I found that many designs incorporate these reverse biased protection diodes on Vusb, D+, and D-, however not all do.

Again, if all of this is mounted on a PCB, why might a sudden static discharge occur and where might it originate?

How frequent is this kind of event and without these diodes is it likely to damage circuitry?

Is it best practice to always include these protection diodes or are they not necessary at times? If the latter, what special cases deem them unnecessary?

Will any diode work or should one with a specific breakdown voltage be used?

EDIT:

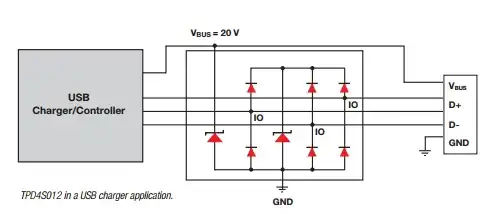

Looking over those App notes, one shows

While the other shows something similar but without the "top" node connected to anything. Is this a misprint or is it implied to be connected to Vbus?