Fuses are a difficult subject. A 5A fuse may remain intact at 7A but blow at 6A. It all depends on how the current pattern is in time. In the glass cylindrical fuses there are fast types (marked "F", actually for the German word "Flink"), which will blow if the rated current is exceeded even for a short time, and there are slow-blow fuses (marked "T", from the German word "Trage"), which will withstand short surges. Most power supplies will use the latter, as they will cause a current peak when switching on.

Self-repairing fuses like PolyFuse are PTC devices whose resistance will rise to very high values if they heat up by a too high current, but they never are a real interruption. When they cool down they will conduct again, and the circuit may operate again, provided the cause for the tripping is removed. Because it has to react to heating a PolyFuse will have a certain resistance, much more than a glass fuse. The size of a PolyFuse will not only depend on its current rating, but also determine how fast it will react. It should be clear that an 0805 part will react faster than a 20mm diameter disc.

edit

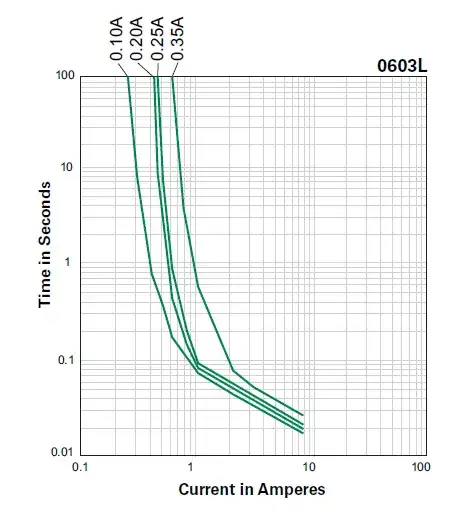

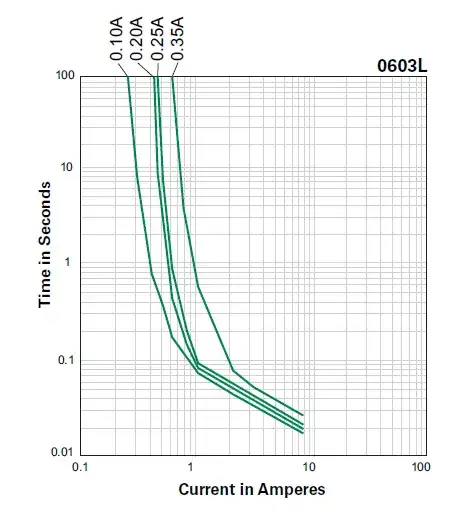

A graph will show how different PTC fuses are from metal wire fuses:

If there's an overcurrent the resistance will rise, reducing the current (1/10th second) quickly to 1/10th of the value, after which the current still will decrease, but much more slowly, and there will always remain a current; you don't get a complete interruption. This is for the small 0603 size SMT version. A radial version like the 600R reacts much more slowly (10 seconds to go to 1/10th of the current), so it's clear that the PolyFuse won't really protect against short-circuits: by the time the current is reduced to a safe level several components may be fried.

What kind of fuse you choose should depend on what you want to protect against. If it's excessive current due to a component defect you don't want a self-repairing device, you want to stop the product working until it has been repaired. (In this answer I explained why this type of fuse shouldn't be user-replaceable.) For a power fuse you don't pick a PTC. OTOH, if high current peaks are normal in your product, but you don't want to over-dimension your components to cope with it, a PTC may help.