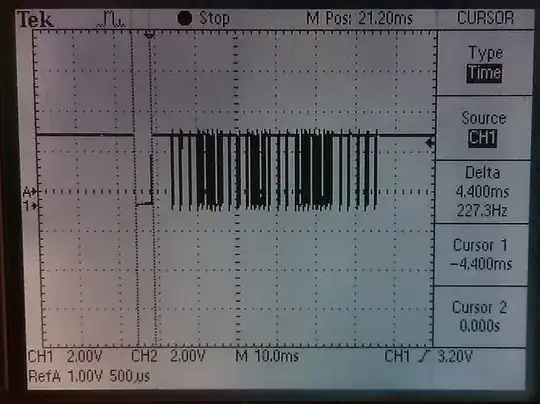

This is what I am talking about (click to enlarge):

It is from an old (1990s) telephone system. There were multiple lines, some digital, some analogue, and in the output stage these modules (double sided) were standing (in a slit) on the main PCB and soldered to it (with the pins you can see).

There were a couple of other sub-PCBs on this thing, but only those were of this ceramic type. So the question is: Why are those printed on ceramic?

It seems that the traces will have higher resistance and the overall building cost for unusual PCBs is often higher than for established processes. On the other hand, this looks like a multilayer, and the other side is a multilayer too, which made me think if this is cheaper than a "real" four-layer PCB (since it has no vias). But then some of the modules (unfortunately I cannot remember anymore which of those was for digital and which for analogue lines) only had one side populated.