Remember that the registration of the drill holes to the copper features will not be perfect. Typically the drill hole center might wander by 4-10 mils from the location you drew it at.

Usually we choose the size of the copper ring around the pad so that with maximum offset of the drill center, no more than maybe 25% of the perimeter of the drilled hole will be outside the pad.

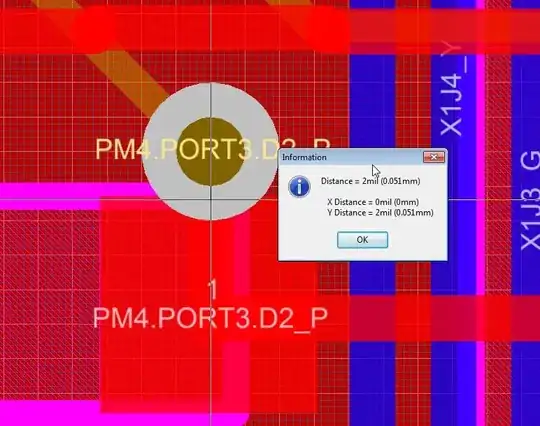

If your hole registration and via pad are designed this way, in your diagram that means the drilled hole could end up with about half its area within the square pad.

If you are designing for mass production, I would not recommend this design. I'd rather either move the via far enough away from the pad to ensure there's a soldermask dam between the pad and the via, or pay for via-in-pad-plated-over (VIPPO).