One of the jobs I often have to perform is repairing the infra-red sensing headsets for BattleSports equipment.

Basically the headset consists of a pair of IR detectors and red LEDs for indication. They are worn on the head, and connect to the BattleSports gun via a coiled (Telephone Handset-style) cable.

One end of this cable has a proper RJ-11 (4P4C) connector, the other end is soldered directly into one of the sensor modules on the headset.

The cable used is really not the best cable in the world.

- It breaks where it enters the gun, even with a rubber grommet

- It breaks where it enters the sensor

- It's not designed to be soldered

And on top of all that while doing the repairs I am finding the actual copper of the wire is getting badly corroded and oxidised by being outside all day every day (kids are not gentle with the kit). The wire gets brittle with the oxidization, and breaks are more common as it ages.

So I ask: is there a better kind of cable that is specially designed to resist oxidisation? I'm not asking for a specific product or anything, just if such a wire exists and what it would be called. From there I can try and source coiled cable, or as a last resort investigate custom cable producers. I just need to know what metal / alloy etc to look for...

Update:

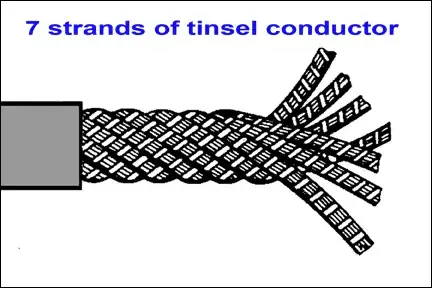

Thanks to @RussellMcMahon I now have a term to search for, and a concept to look into. It just so happens that I bought a headset cable to try out to see if it was any good - closer examination shows that it is indeed made from this "Tinsel Cable" that Russell mentions.

And yes, I can attest that it is almost impossible to solder it.

For more detail here's some pictures of the headset end.

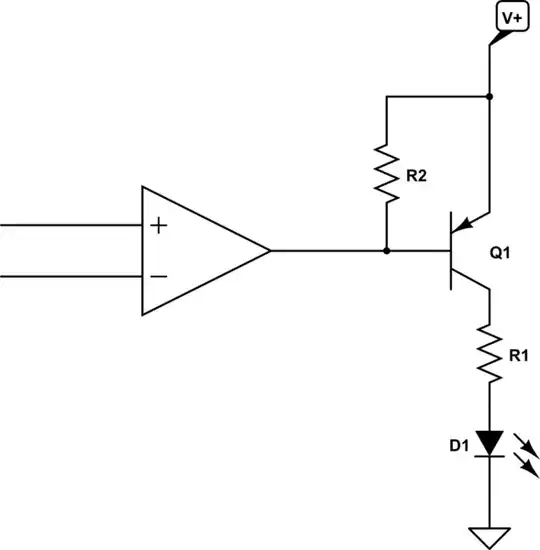

This is one of the two sensors:

The wire enters between the casing and the circuit board:

(That's fluff,by the way, not blood :P ). The wire is soldered direct to the circuit board (surface mount pads):

That's my attempt at soldering the tinsel wire there...

The most common break at the headset end is at the point the wire enters into the plastic casing. There's quite a bit of crimping pressure placed on the wire at that point, and bends there are usually fatal.